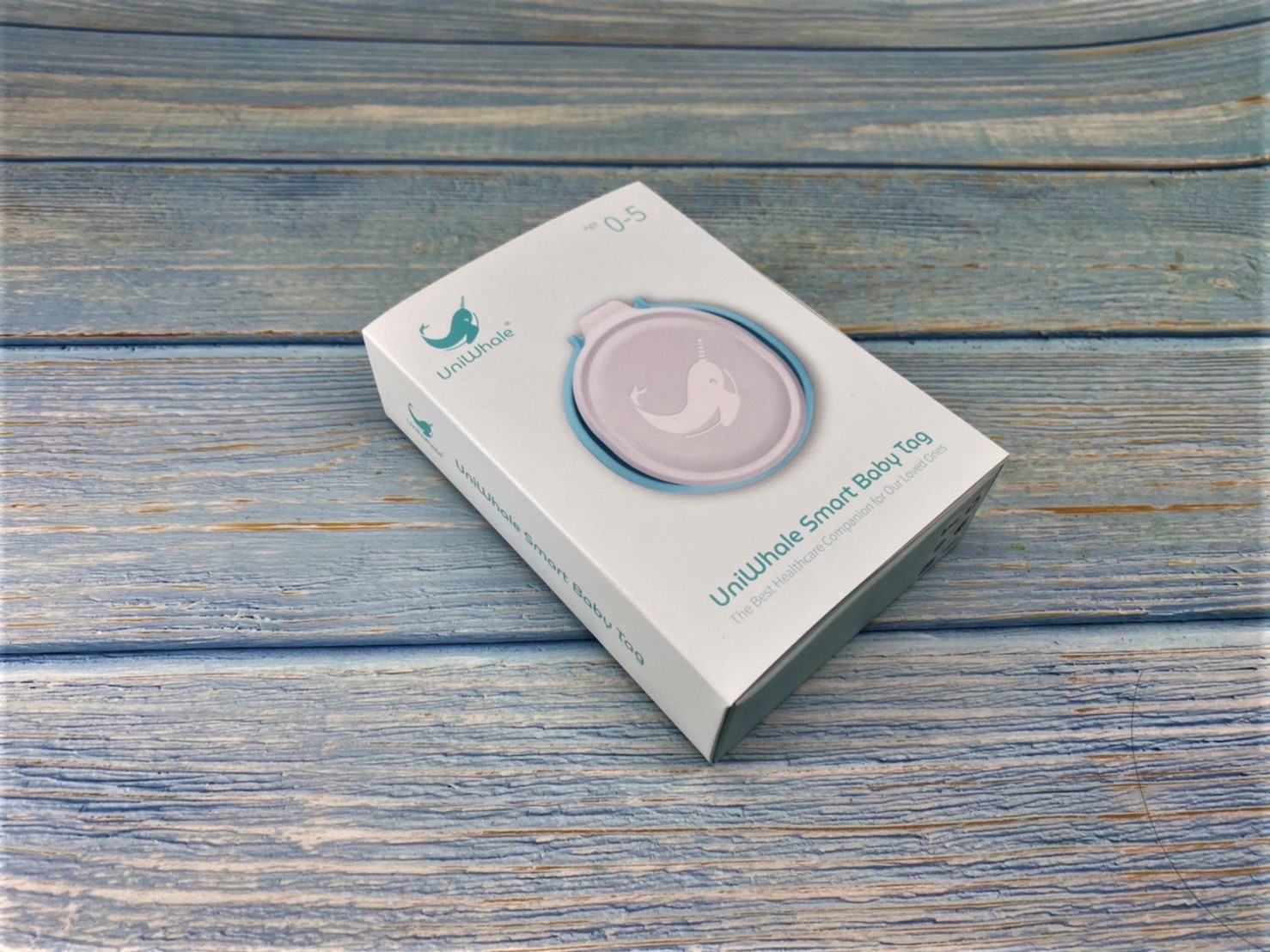

Cosmetic Packaging

- Needs Analysis and Design: Begin by clearly understanding the client's requirements and brand image. This involves the overall design concept, colors, patterns, and typography. Designers and printing suppliers collaborate to finalize the design concept.

- Choosing Suitable Materials: Selecting the right packaging material is crucial based on product nature and design requirements. Common materials include plastic, glass, metal, and specialty materials like tubes. Material choice impacts not only the packaging's appearance and texture but also printing quality and durability.

- Printing Techniques and Effects: Choose appropriate printing techniques according to design requirements. Common techniques include offset printing, screen printing, foil stamping (gold/silver stamping), and digital printing. Each technique offers unique advantages; for instance, offset printing suits large-area patterns and vibrant colors, while foil stamping adds a luxurious feel and visual appeal.

- Special Effects and Surface Treatments: Enhance the visual and tactile appeal of the packaging with special surface treatments such as gloss coating, matte coating, UV coating, spot gloss, or matte effects. These treatments elevate the packaging's sophistication and premium appearance.

- Regulations and Compliance: Ensure compliance with local regulations and standards, particularly concerning printing inks and material safety for cosmetic packaging. Selected printing materials and techniques must meet safety standards and environmental requirements.

- Sample Approval and Production: Before mass production, create samples for client approval. This step ensures the final packaging printing meets expectations and satisfies customer requirements.

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

Hans International Printing Co., Ltd.

Adress: 4th Floor, No. 6, Lane 63, Huacheng Road, Xinzhuang District, New Taipei City 242, Taiwan (ROC)

Hans Printing Specialist Mr.Huang Mobile :+ 866 910243496

Hans Printing Specialist Ms.You Tel:+886 2 29982117 #399

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.

The content related to paper box printing production:

- Size Format: Dimensions of the paper box in length x width x height in centimeters.

- Paper Types: Single copperplate, gray copper card, drill card paper, watermarked white card paper, white copper card paper, copper west card paper, art paper (imported paper).

- Mounting Corrugated Paper: Mounting E wave, mounting white E wave, mounting B wave, mounting F wave, mounting kraft paper, mounting E wave + B wave.

- Paper Thickness: Paper thickness (250 pounds, 300 pounds, 350 pounds, 400 pounds, 500 pounds, 600 pounds).

- Printing Colors: Six-color printing, five-color printing, four-color printing, two-color printing, monochrome printing.

- Printing Quantity: Quantity.

- Sampling Method: Digital sampling or formal sampling (direct machine printing sampling or sampling).

- Die Cutting Types: General die cutting, Japanese die cutting, Swiss die cutting, steel die cutting, laser die cutting, metal die cutting.

- Box Surface Treatment: Water-based gloss, gloss, matte, suede, frosted, matt, or partial gloss, UV gloss (UV is divided into gloss UV, frosted UV, release UV).

- Special Techniques: Skylight, hand-held handle, transparent film pasting, hot stamping gold and silver, copper button pressing.

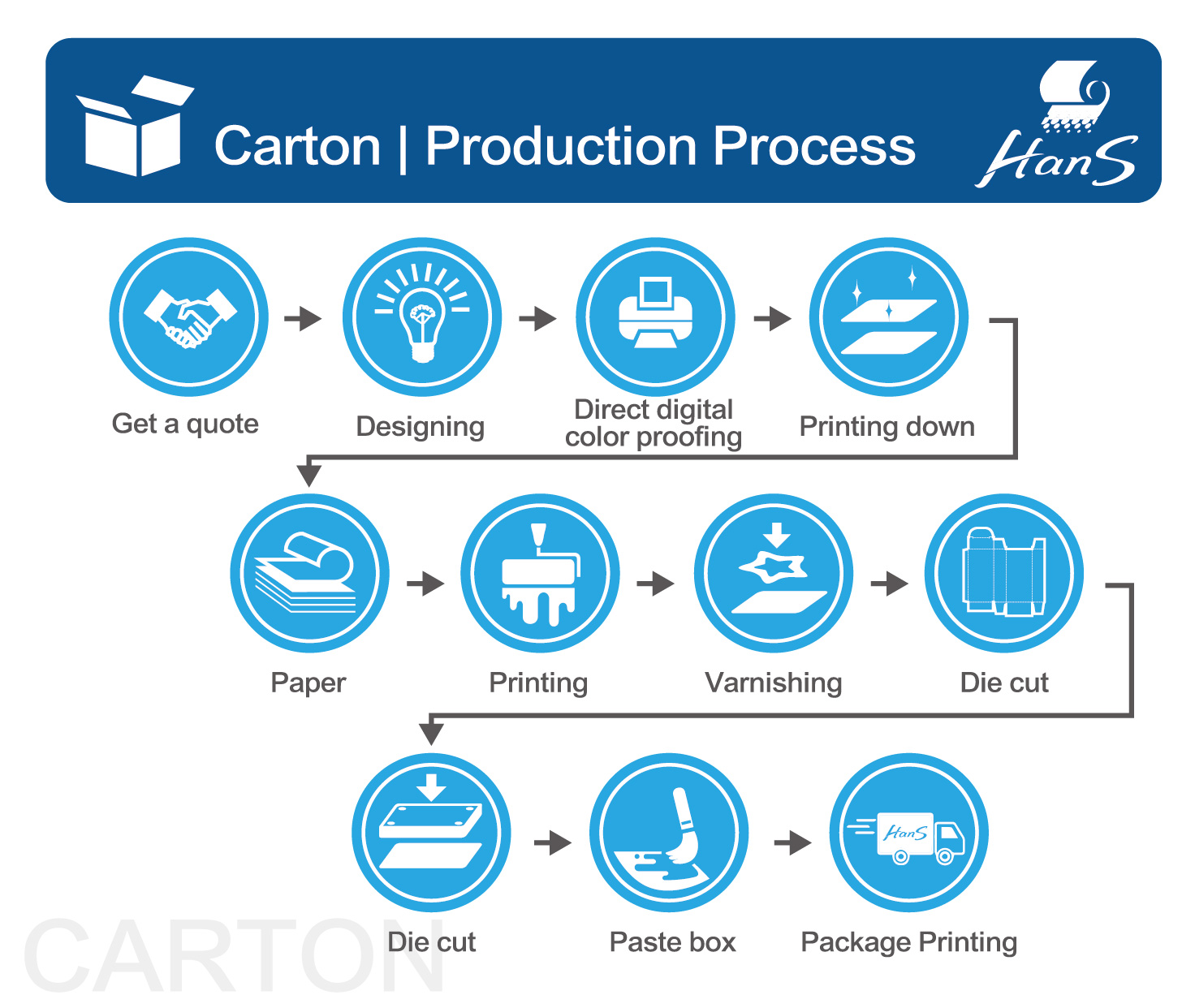

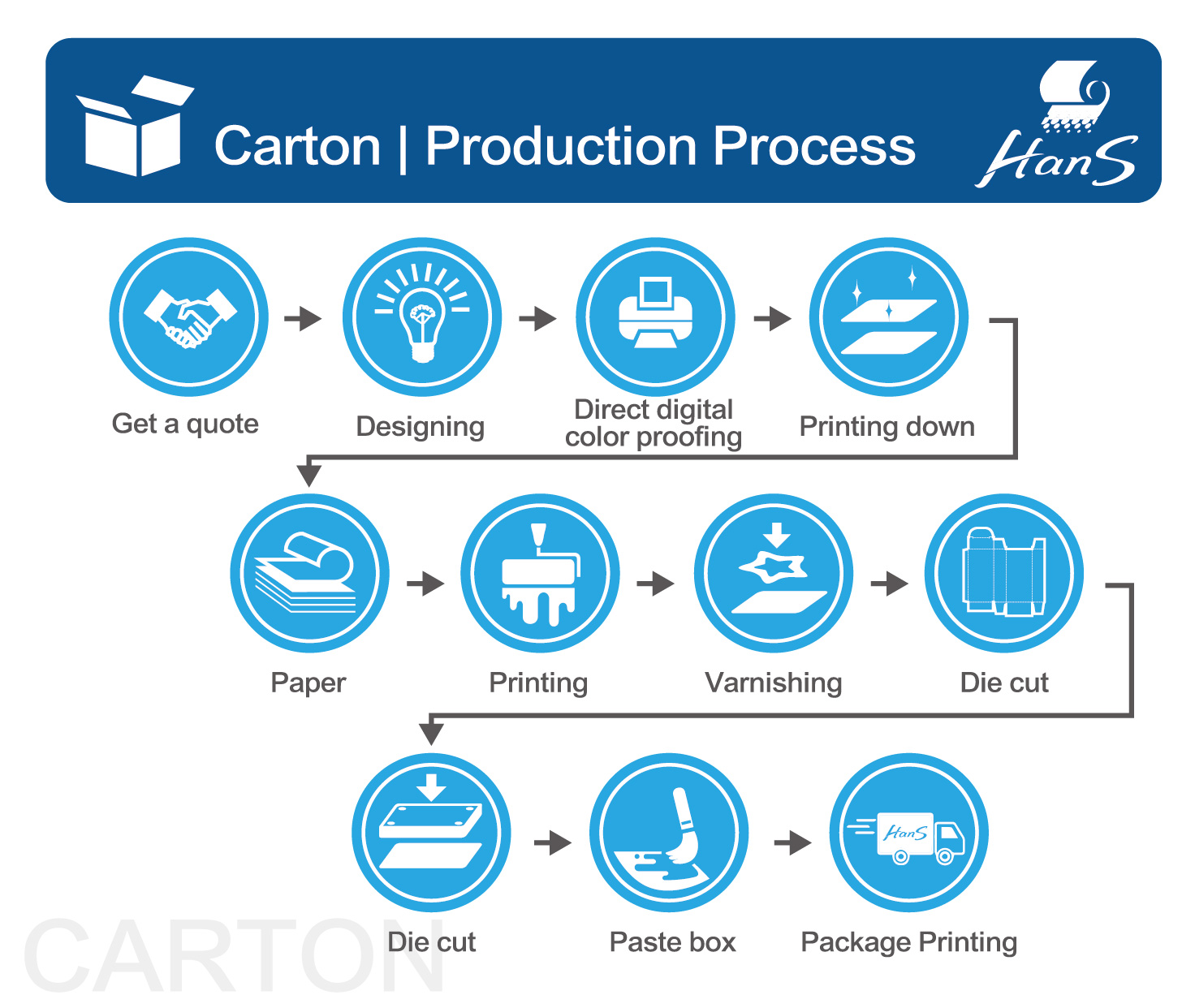

The paper boxes printing production process:

Quotation and contract signing ==> Design ==> Final draft editing ==> Proofreading ==> Digital sample printing (for formal sample) ==> Paper printing ==> Mounting on corrugated board ==> Plate exposure ==> Printing ==> Glossing ==> Die cutting ==> Assembly ==> Handmade box ==> Packaging and shipping (1-month process)

, Cosmetic box packaging design, Luxury cosmetic packaging boxes, Cosmetic packaging for small business, Cosmetic packaging boxes empty, Cosmetic box packaging design