PVC Box Packaging Printing

-

sentiment_very_satisfied

Viewers:

- 1,059

PVC box packaging printing kit, plastic box packaging, sample box plastic, plastic box manufacturing, hard plastic box, plastic container box

1. Printing Methods:

- Screen Printing: Suitable for PVC due to its ability to adhere to various surfaces. It works well for solid colors and simple designs.

- Offset Printing: Ideal for high-volume production and complex designs. It offers good color reproduction and detail.

- Digital Printing: Offers flexibility for short runs and variable data. Can achieve photo-quality prints and is cost-effective for smaller quantities.

2. Preparation and Surface Treatment:

- Surface Cleaning: PVC surfaces should be thoroughly cleaned and dried before printing to ensure adhesion and print quality.

- Surface Treatment: Depending on the printing method, a primer or surface treatment might be necessary to improve ink adhesion and durability.

3. Ink Selection:

- UV-curable Inks: Commonly used for PVC due to their ability to cure quickly and adhere well to plastic surfaces.

- Solvent-based Inks: Also effective but may require longer drying times and adequate ventilation due to their chemical composition.

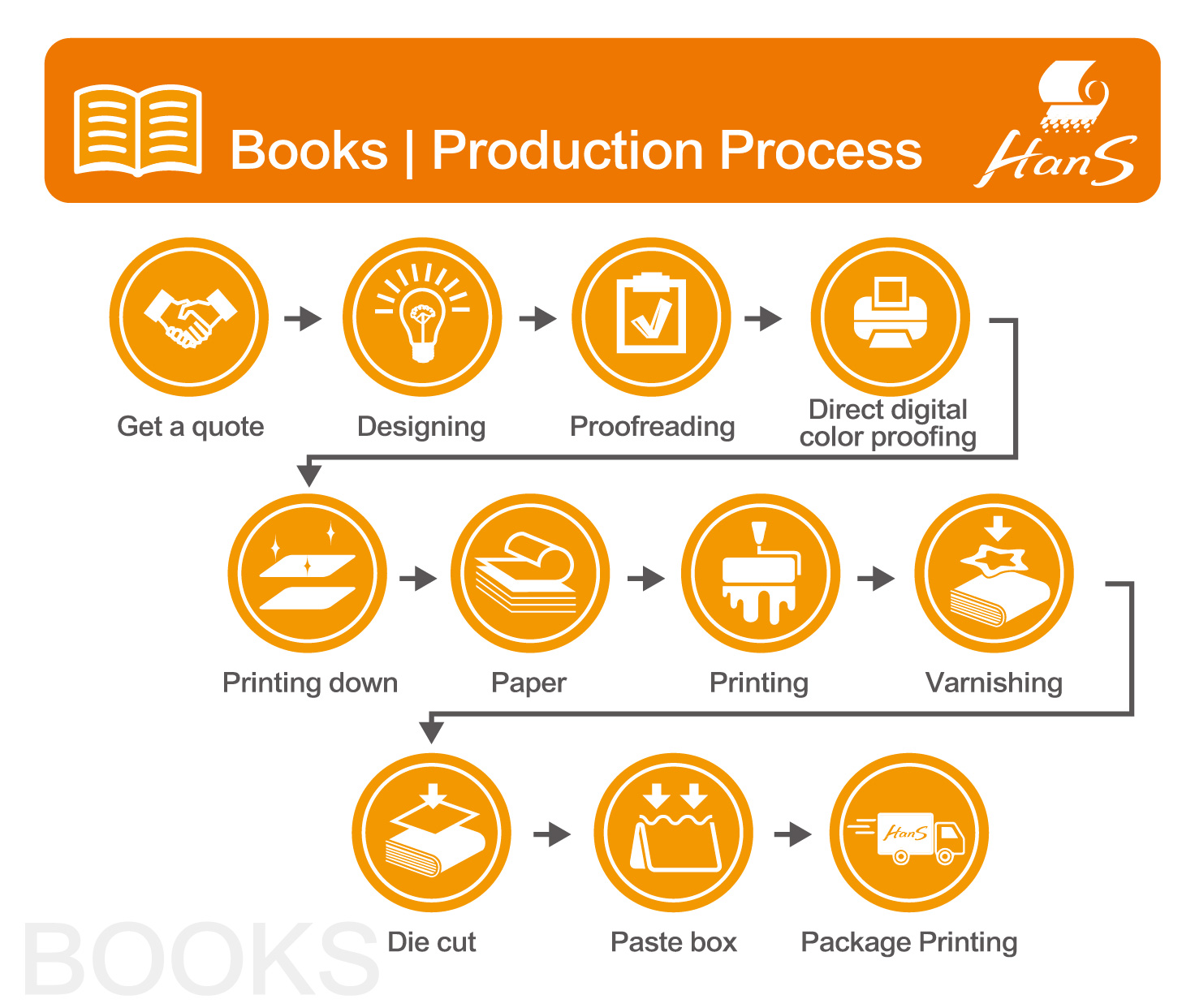

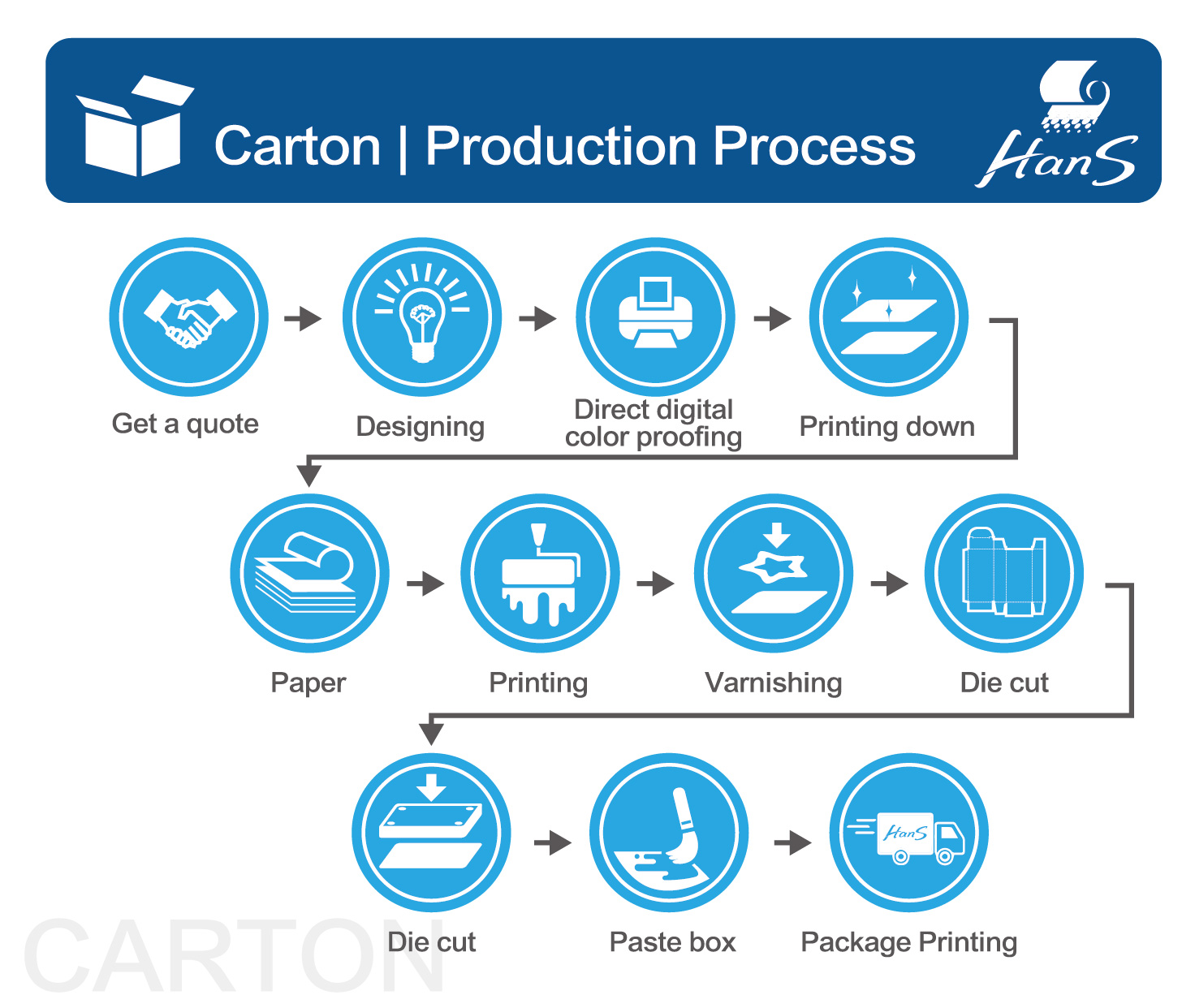

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.

Transparent Box Printing Production

(Printing Area Maximum 102x72 cm) (Minimum Printing 36.5x54.5 cm)

● Size of Transparent Plastics: Length x Width x Height cm.

● Types of Transparent Plastics: PVC, PET, PP, Foil (Gold, Silver), Laser Paper, Dyed White/Black PVC, or Special Papers.

● Number of Transparent Strips: Thickness (0.18, 0.2, 0.25, 0.3, 0.35, 0.4, 0.5, 0.6 strips).

● Printing Colors: Five to Six Color Printing, Four Color Printing, Two Color Printing, Monochrome Printing (White ink required for transparent backgrounds).

● Printing Quantity: Quantity of Transparent Boxes.

● Sample Method: Digital Sample or Formal Sample (typically direct machine sampling).

● Die-cut Types: Japanese Die-cut, Swiss Die-cut, Steel Die-cut, Laser Die-cut, Metal Die-cut.

● Gloss on Transparent Plastics: Glossy, Matte, Velvety, Frosted, Satin, Anti-scratch Matte, Anti-stick Oil, (Release UV).

● Special Techniques: Hot Stamping (Gold, Silver), Silver Printing, Gold Printing.

The Transparent Box Printing Production Process:

Quotation and contract signing ==> Design ==> Final draft editing ==> Proofreading ==> Digital sample printing (for formal sample) ==> Paper printing ==> Mounting on corrugated board ==> Plate exposure ==> Printing ==> Glossing ==> Die cutting ==> Assembly ==> Handmade box ==> Packaging and shipping (1-month process)

pvc print meaning,pvc card printing price,can you print on pvc,plastic box printers