Softcover Book Printing

-

sentiment_very_satisfied

Viewers:

- 471

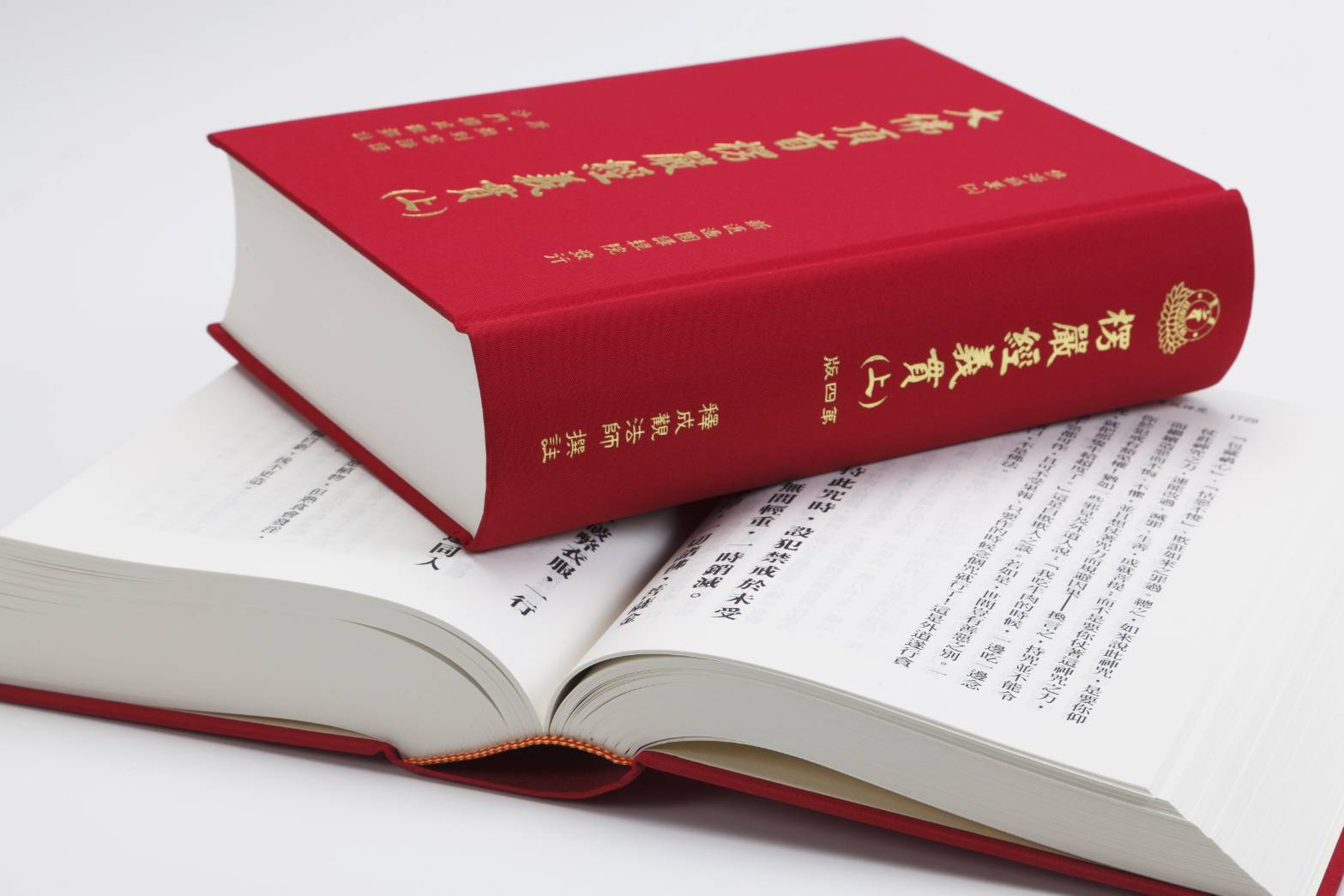

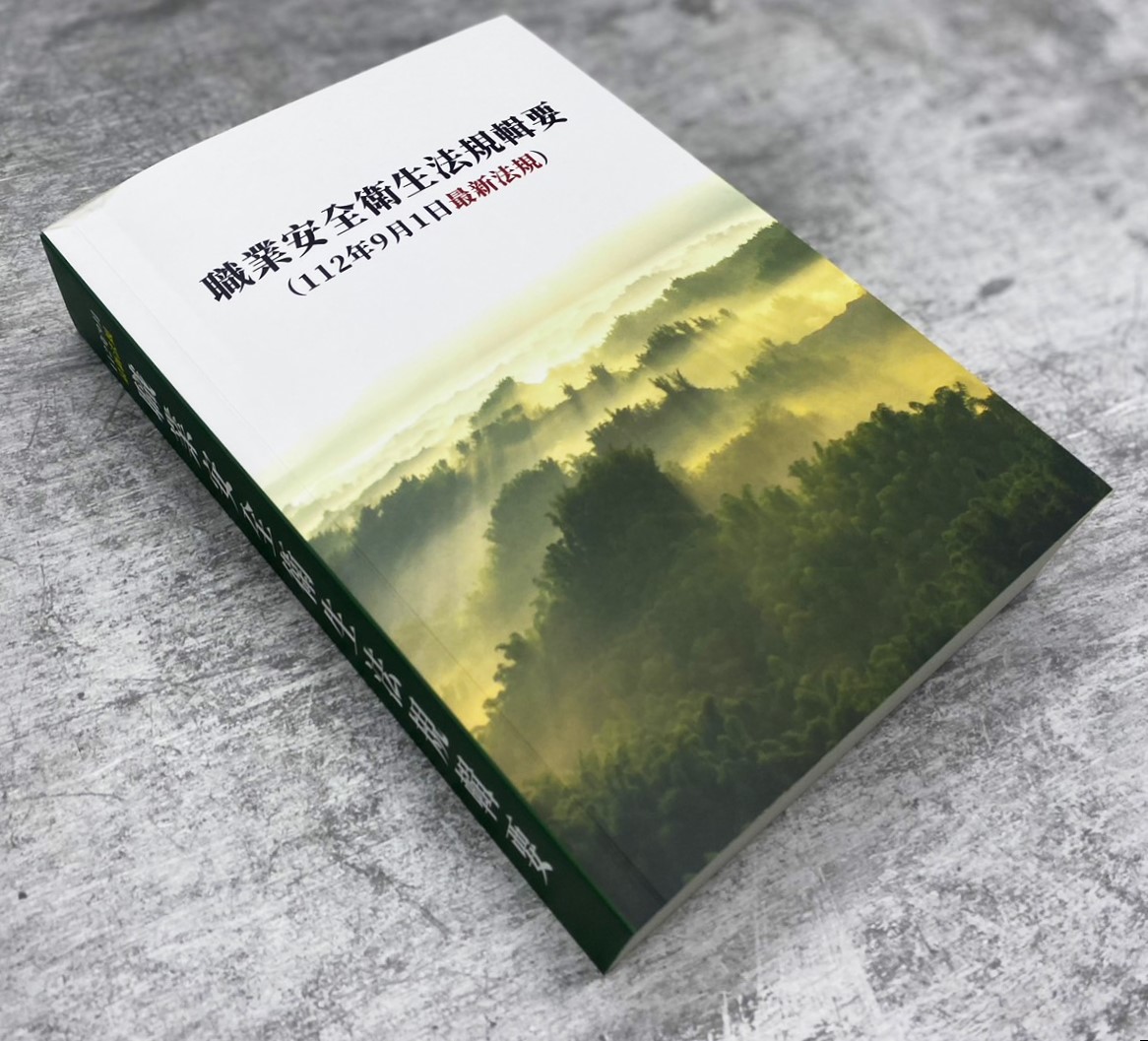

Softcover books—also known as paperback books—are lightweight, cost-effective, and easy to carry—making them a popular choice for a wide range of publications. The most common binding method is perfect binding, which provides a sleek finish and durable structure for multi-page formats.

This method is ideal for novels, catalogs, manuals, educational books, and reports. From expert material recommendations to precise binding and protective packaging, we ensure every book delivers exceptional quality and long-lasting performance—exceeding your expectations.

Design & Specifications

Product Requirements

- Define book dimensions, page count, and weight based on content and usage.

- Consider the target audience and storyline to determine special sizes or paper types.

Brand & Graphics

- Integrate logos, colors, and visual themes to maintain brand consistency.

- Ensure cover and interior layout align with the tone and style of the theme.

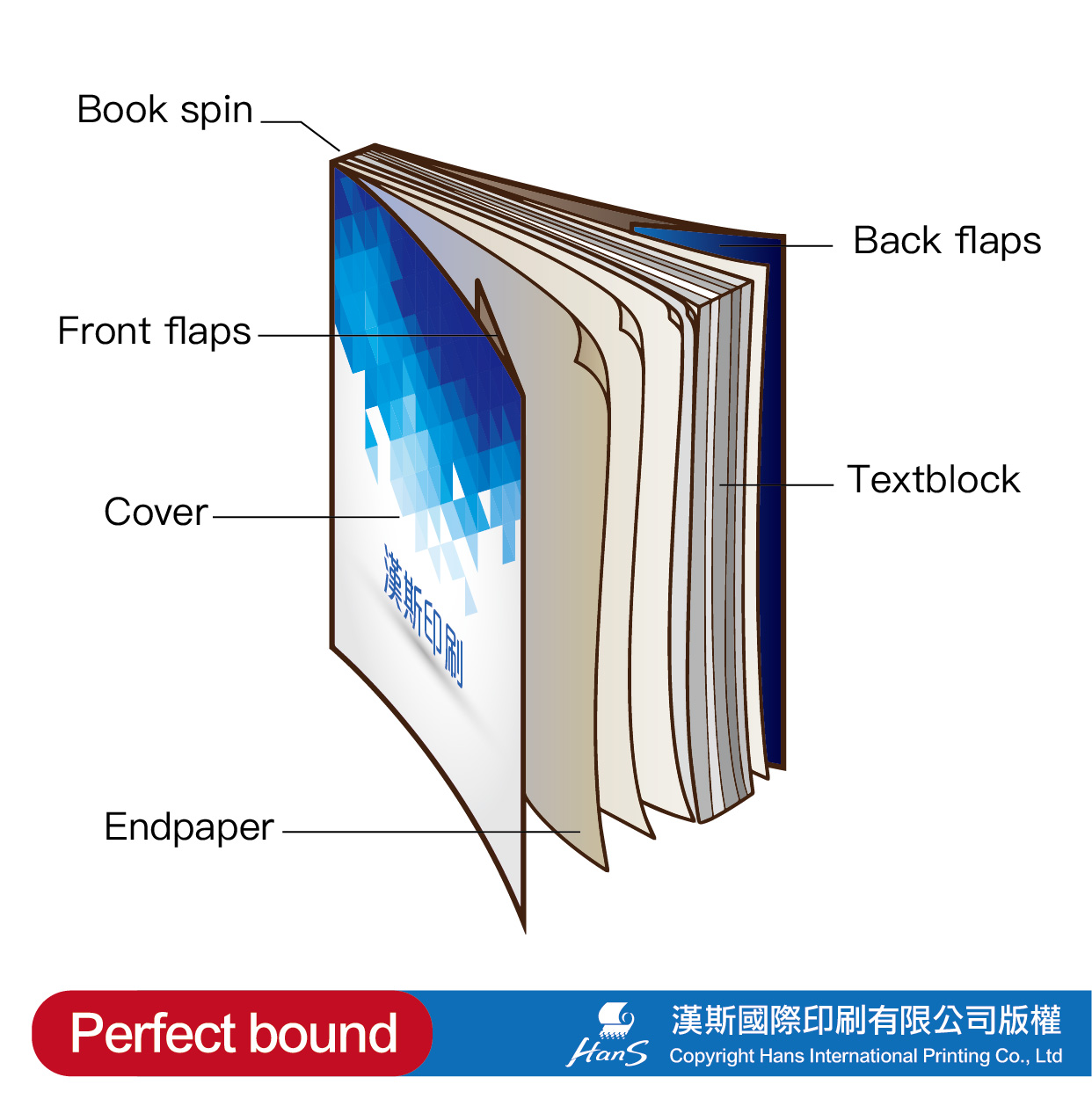

Structural Design

- Design for durability and ease of handling.

- Ensure page and cover sizes are optimized for binding and readability.

Material Selection

- Paper Choice

- Select paper thickness and texture based on budget and design.

- Balance glossiness for color vibrancy and reading comfort.

- Printing Methods

- Choose offset, digital, or screen printing based on volume and complexity.

- Ensure accurate color reproduction and detail clarity.

Prototyping & Testing

- Produce prototypes to verify print quality and structural integrity.

- Test durability, stacking strength, and paper performance.

Production & Finishing

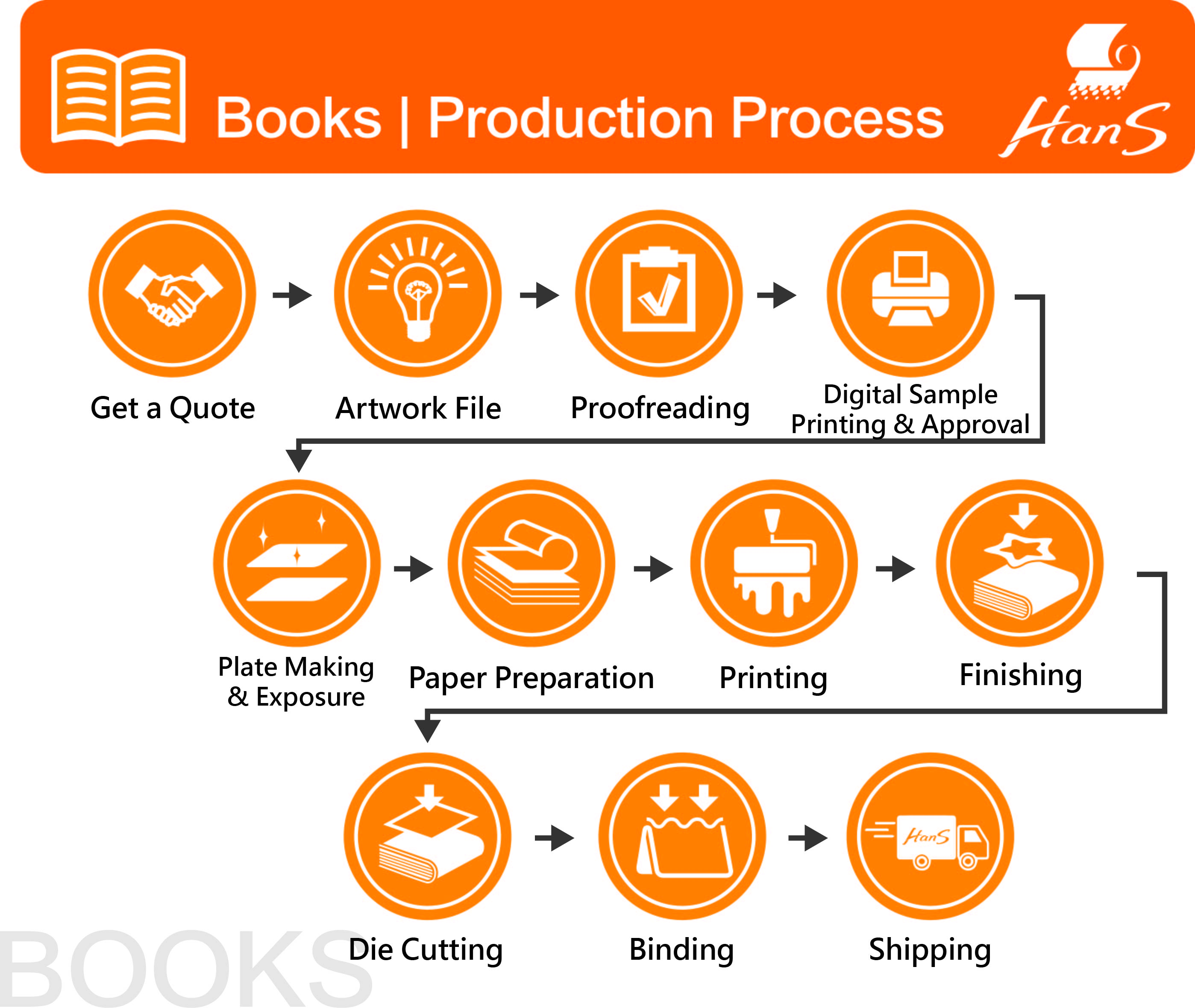

- Production Process

- Define workflow using professional printing and binding equipment.

- Monitor quality and schedule to ensure timely delivery.

- Finishing Options

- Enhance visual appeal with foil stamping, embossing, lamination, etc.

Binding & Packaging

- Implement efficient folding, gluing, and packaging procedures.

- Add inserts or fillers to protect books during transport.

Softcover Book Options & Specifications

******************************************************************************

Drop Your Question!

We’re here to help—feel free to reach out anytime.

- Email: han666@hanfom.com

WhatApp Business: +886 910 243 496

- Ms. Christine — International Sales Representative

Mobile/WhatsApp: +886 910 225 861

(Available GMT+8: 08:30-12:00 | 13:00-17:30 | 21:00-22:00)

- Mr. Huang — Domestic Sales Representative / Printing Specialis

Mobile: +886 910 243 496

(Available GMT+8: 08:00-20:00)