Poker Card Printing Process

-

sentiment_very_satisfied

Viewers:

- 2

|

|

|

|

Poker Cards Printing Specifications

Size:

|

Paper Types:

|

Paper thickness options:

|

Printing Colors:

|

Paper or Box Finish:

|

Printing Quantity:

|

Die-cut Types:

|

Sampling Method:

|

Processing Methods:

|

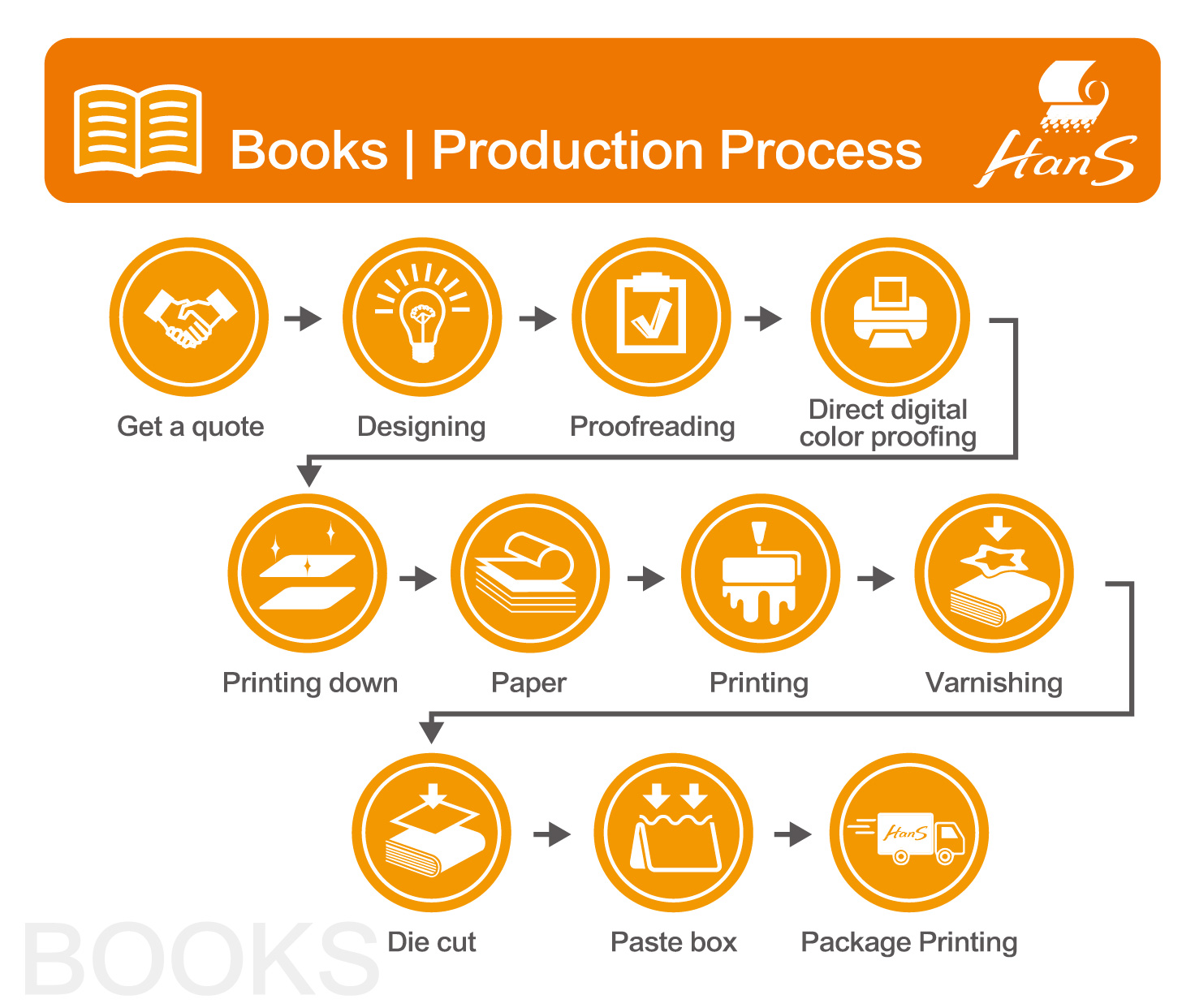

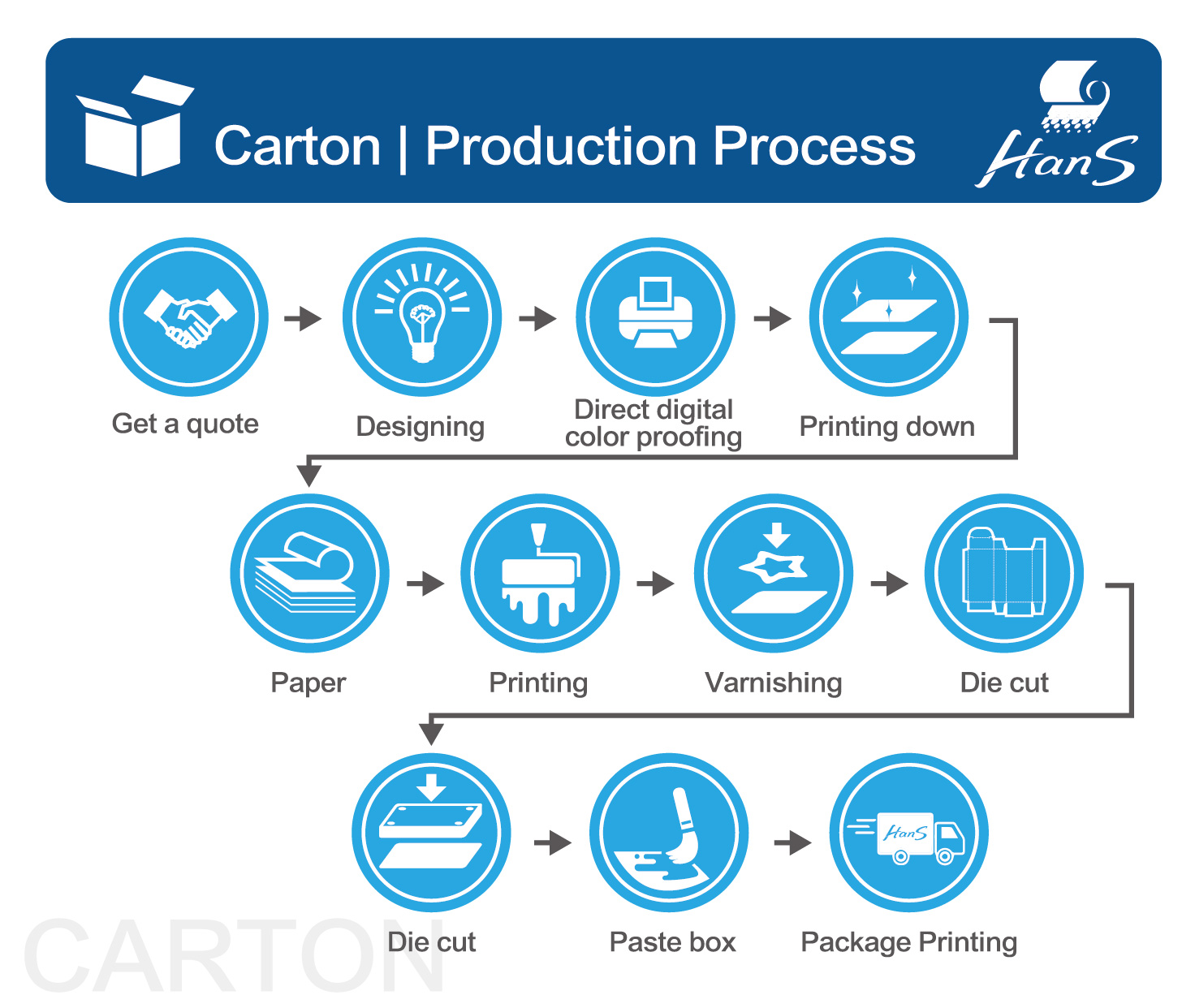

The playing cards printing production process

| 1. Quotation contract ==> | 2. Design ==> | 3. Final draft editing ==> |

|

4. Proofreading ==> |

5. Digital sample printing (for formal sample) ==> |

6. Paper printing ==> |

| 7. Plate exposure ==> | 8. Card Printing ==> |

9. Glossing ==> |

| 10. Die cutting ==> | 11. Assembly ==> |

12. Packaging and shipping |

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.