Varnishing Printing

-

sentiment_very_satisfied

Viewers:

- 962

In the printing industry, varnishing refers to the application of a coating onto printed materials to achieve various effects and enhance their appearance and durability. Here are some common types of varnish used in printing:

1.Gloss Varnish: This type of varnish provides a shiny and reflective finish, enhancing colors and giving printed materials a polished look. It's often used to make colors appear more vibrant.

2.Matte Varnish: Matte varnish has a non-reflective finish that reduces glare and provides a smooth, elegant appearance. It can give printed materials a sophisticated and understated look.

3.Satin Varnish: Satin varnish offers a finish that falls between gloss and matte. It provides some shine while maintaining a soft, smooth texture, making it suitable for various design styles.

4.Spot Varnish: Spot varnish is applied to specific areas of the printed piece rather than covering the entire surface. It creates contrast by highlighting particular elements like logos, images, or text.

5.Soft Touch Varnish: Also known as velvet or tactile varnish, soft touch varnish provides a luxurious tactile feel similar to velvet or suede. It enhances the perceived quality of printed materials and adds a unique sensory experience.

6.UV Varnish: UV varnish is cured using ultraviolet light, resulting in a very hard and durable finish. It provides excellent protection against scuffing, scratches, and fading, making it ideal for high-impact packaging and marketing materials.

7.Aqueous Varnish: Aqueous varnish is water-based and provides a glossy or matte finish. It's eco-friendly and offers good resistance to scuffing and smudging, enhancing the overall durability of printed products.

Choosing the right type of varnish depends on factors such as the desired appearance, the substrate material (paper, cardboard, etc.), and the intended use of the printed materials (packaging, marketing collateral, etc.). Each type of varnish has its advantages and can be customized further with options like textured finishes or special effects.

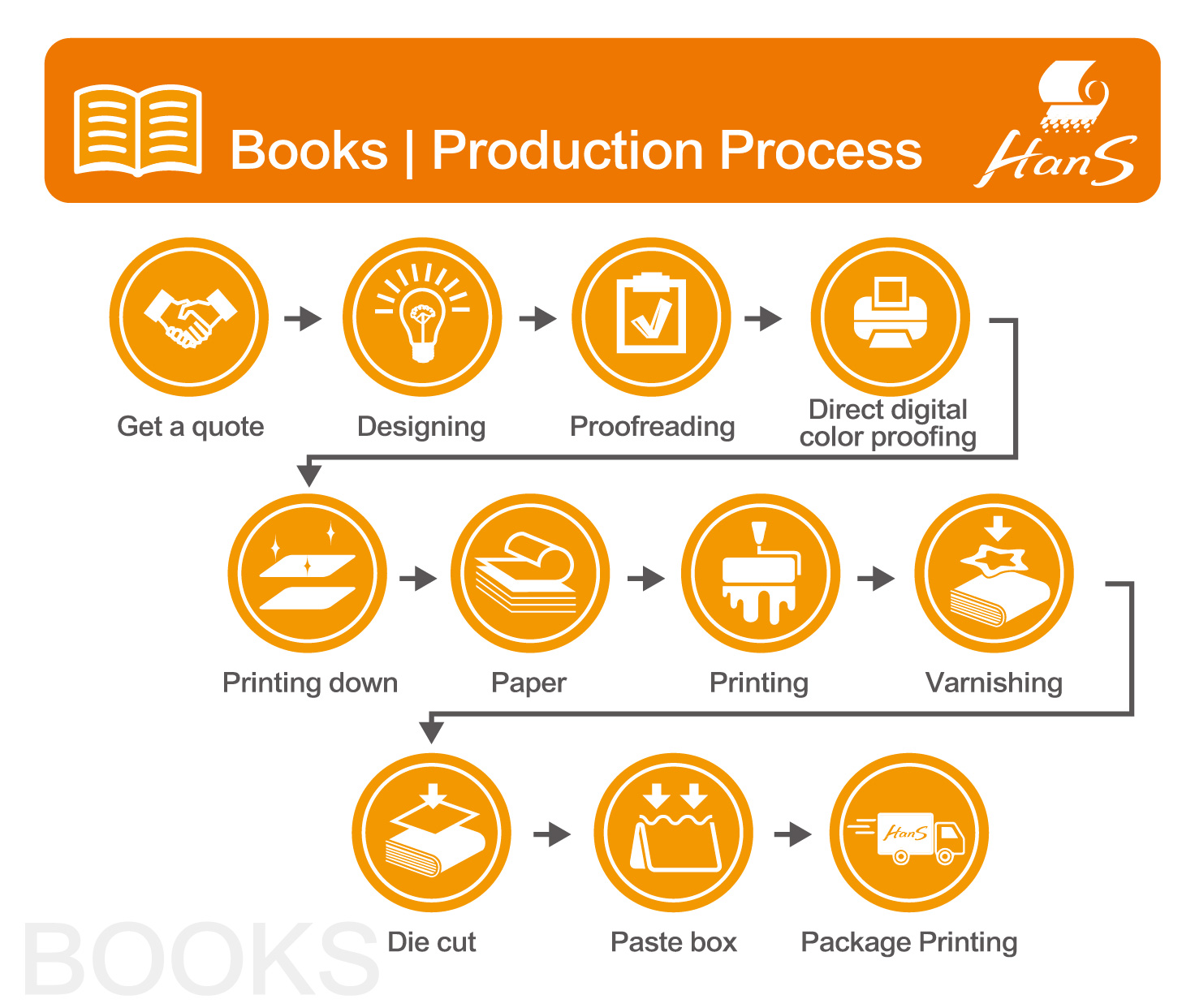

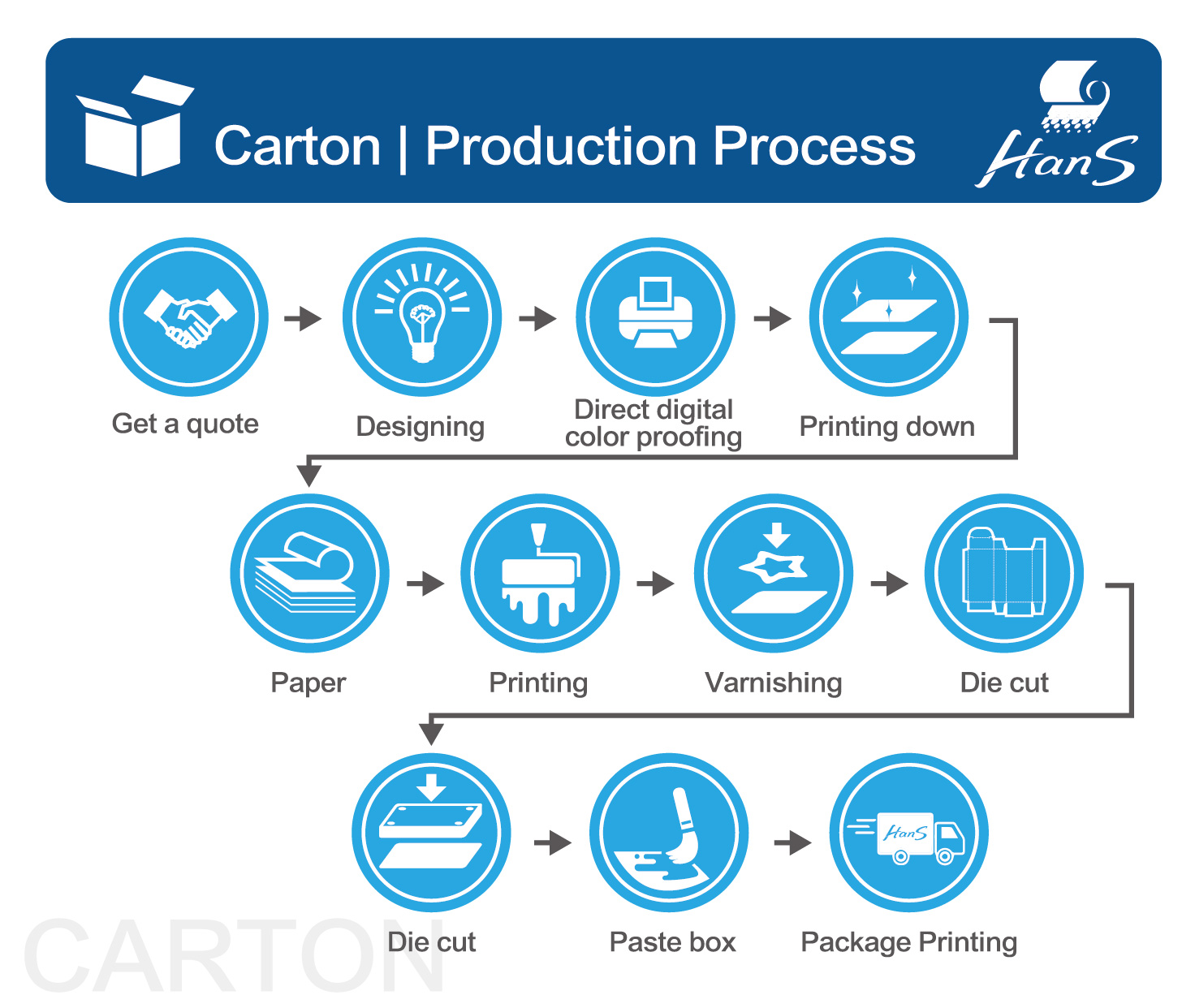

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.