Lamination

-

sentiment_very_satisfied

Viewers:

- 0

Lamination printing involves applying a thin plastic film to the surface of printed materials to enhance their durability, appearance, and functionality. This protective layer helps safeguard against wear, tear, moisture, and other environmental factors, making laminated prints more robust and long-lasting.

• Types of Lamination

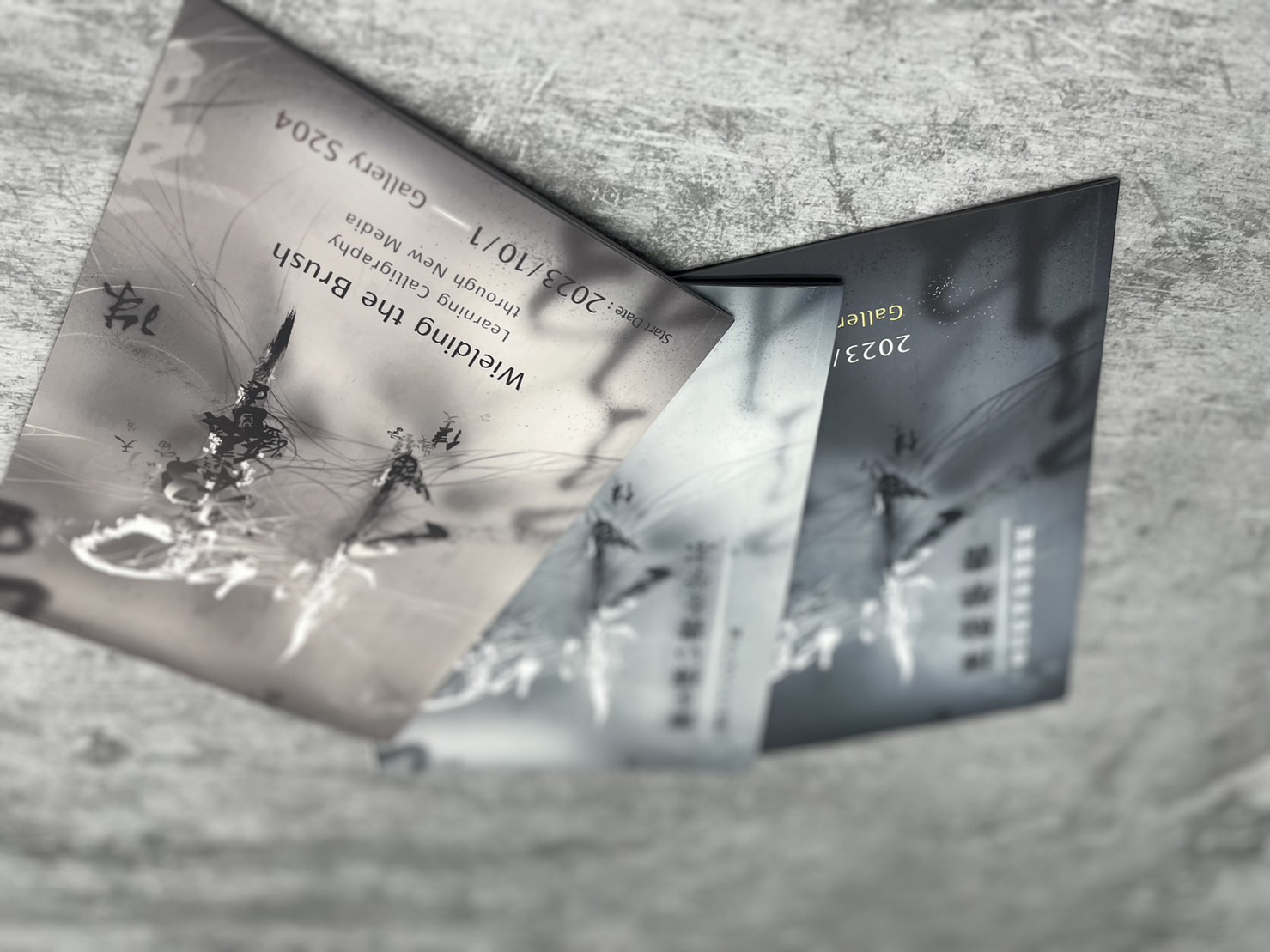

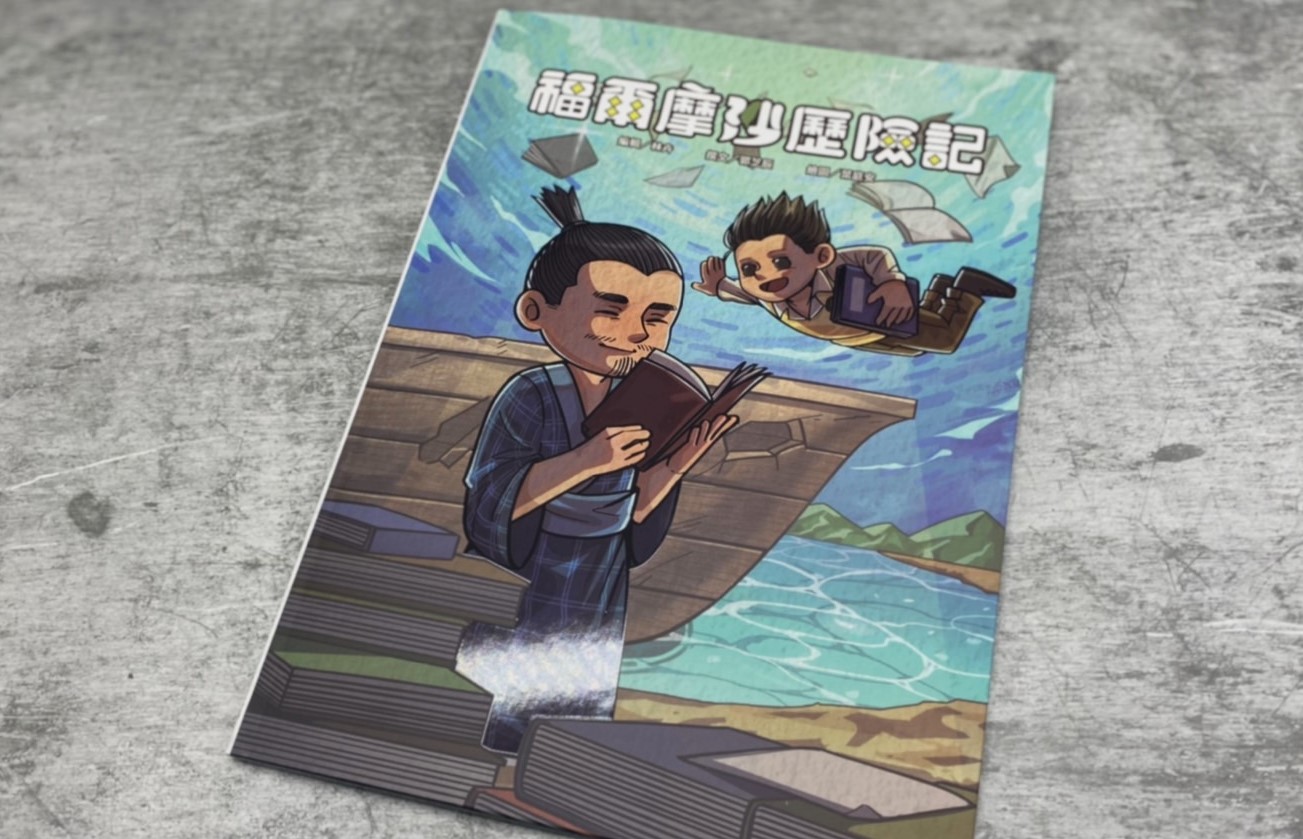

1. Gloss Lamination:- Provides a shiny, reflective finish. - Enhances colors and contrast, making images appear more vibrant. - Commonly used for promotional materials, book covers, and packaging.

|

2. Matte Lamination:- Offers a smooth, non-reflective finish. - Reduces glare and provides a more sophisticated, elegant look. - Ideal for products that require a subdued appearance, such as high-end brochures and business cards. |

3. Satin Lamination:- Provides a finish that is between gloss and matte. - Balances the benefits of both gloss and matte lamination. - Used for materials where a moderate sheen is desired. |

4. Soft-Touch Lamination:- Offers a luxurious, velvety feel. - Adds a premium tactile quality to printed materials. - Commonly used for high-end packaging, covers, and marketing materials. |

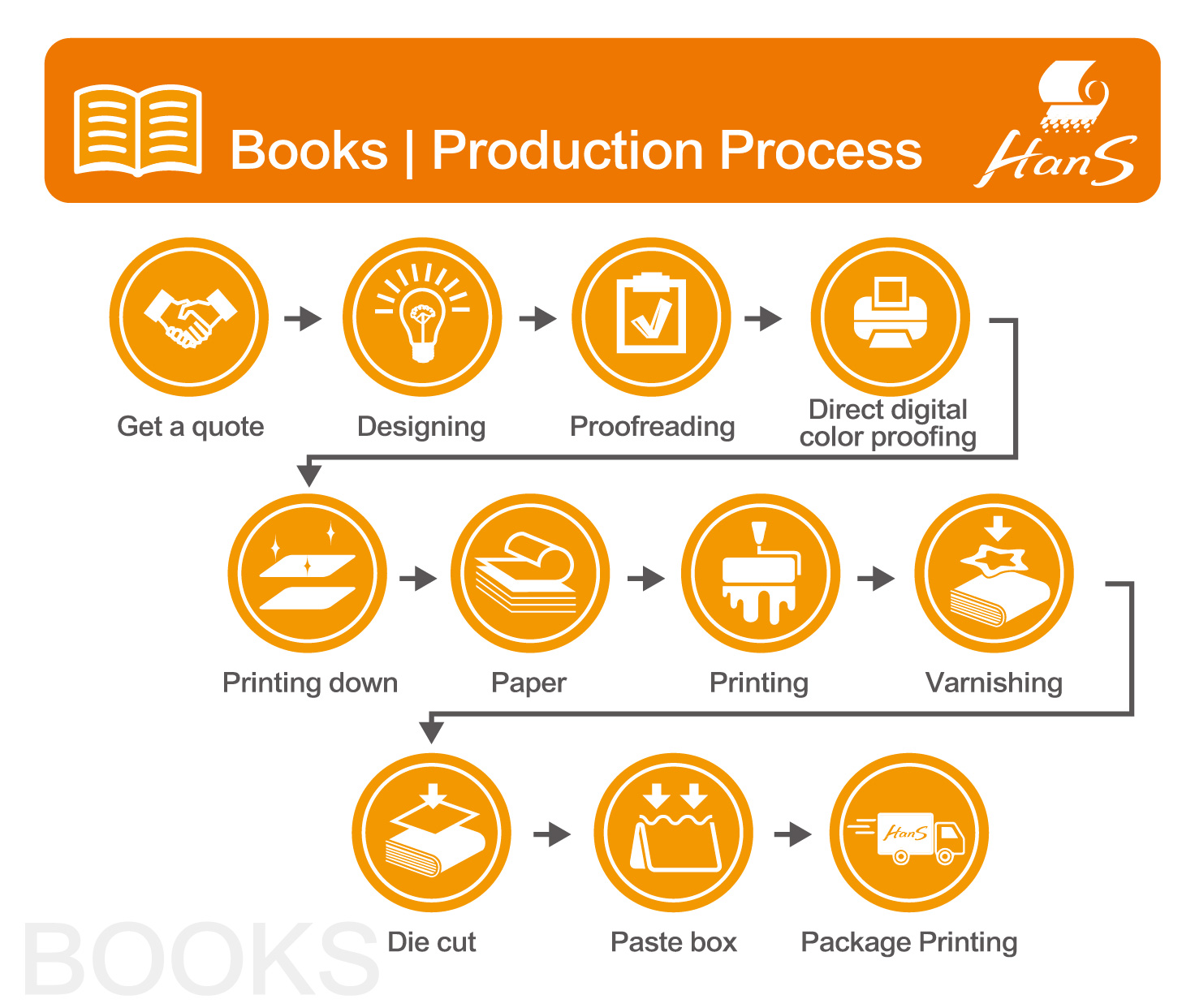

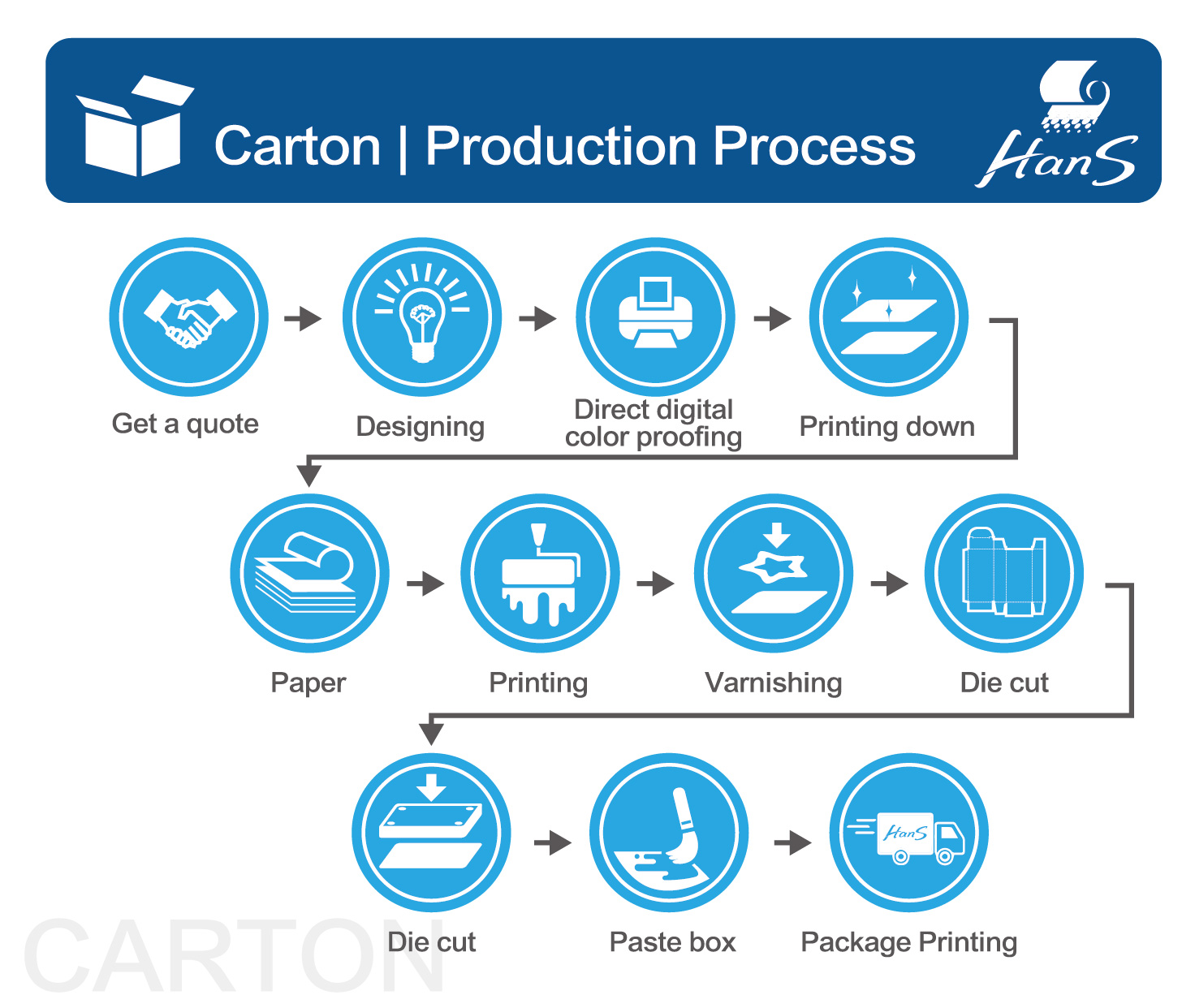

• Process of Lamination Printing

1. Preparation:- Print the material to be laminated. - Ensure the print is completely dry and free from dust and debris. |

2. Film Application:- Choose the appropriate lamination film (gloss, matte, satin, or soft-touch). - Place the printed material into the laminating machine. |

3. Heat and Pressure:- The laminating machine applies heat and pressure to bond the film to the printed material. - The adhesive on the film activates and securely attaches to the surface. |

4. Trimming:- After lamination, trim any excess film from the edges. - Ensure clean and even borders for a professional finish. |

• Advantages of Lamination Printing

1. Durability:- Protects printed materials from damage caused by handling, moisture, and environmental factors. - Extends the lifespan of printed items. |

2. Appearance:- Enhances the visual appeal with various finishes (gloss, matte, etc.). - Improves color vibrancy and sharpness. |

3. Protection:- Guards against fingerprints, smudges, and spills. - Makes materials easier to clean and maintain. |

4. Versatility:- Suitable for a wide range of printed items, including business cards, menus, book covers, posters, and more. - Applicable to both single-sided and double-sided prints. |

• Limitations of Lamination Printing

1. Cost:- Adds additional expense to the printing process. - May not be cost-effective for short runs or budget-conscious projects. 2. Environmental Impact:- Uses plastic films, which can be less environmentally friendly. - Disposal and recycling of laminated materials may be challenging. 3. Suitability:- Not suitable for all types of prints (e.g., items that need to be written on). - Some lamination films may affect the texture or flexibility of the material. |

• Applications of Lamination Printing

|

1. Business Cards:- Adds durability and a premium feel. - Makes cards more resistant to wear and tear. |

.jpg) |

|

2. Menus:- Protects against spills and frequent handling. - Ideal for restaurants and cafes. |

|

|

3. Book Covers:- Enhances appearance and protects against damage. - Common for softcover and hardcover books. |

|

|

4. Posters and Flyers:- Improves longevity and visual impact. - Suitable for promotional materials displayed in high-traffic areas. |

|

|

5. Educational Materials:- Protects charts, maps, and other educational resources from frequent use. - Makes materials easy to clean and reusable. |

|

• Conclusion

Lamination printing is a valuable process that enhances the durability, appearance, and functionality of printed materials. By choosing the appropriate type of lamination and understanding its benefits and limitations, you can create high-quality, long-lasting prints that meet your specific needs.

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.