Hot Stamping

-

sentiment_very_satisfied

Viewers:

- 0

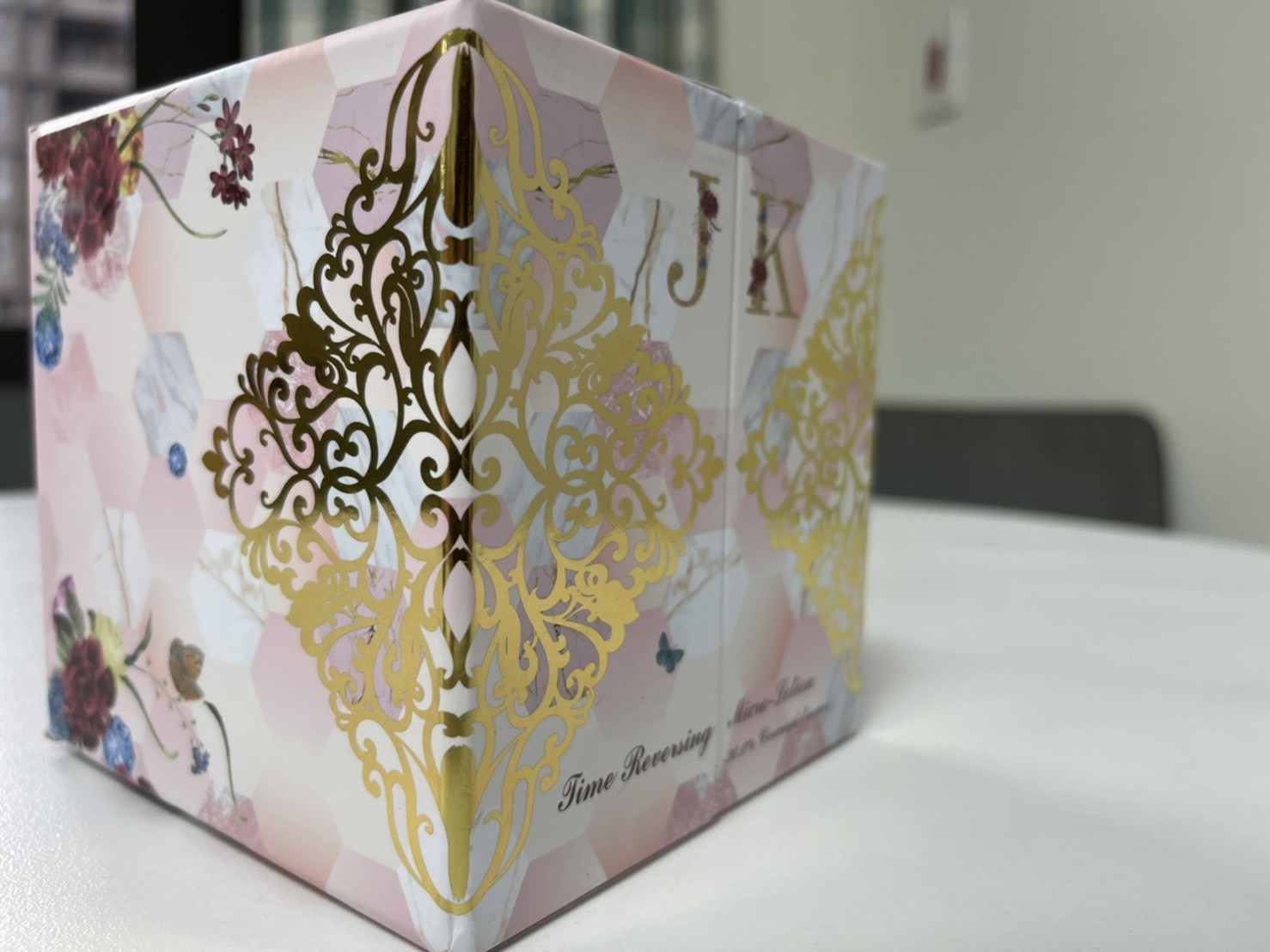

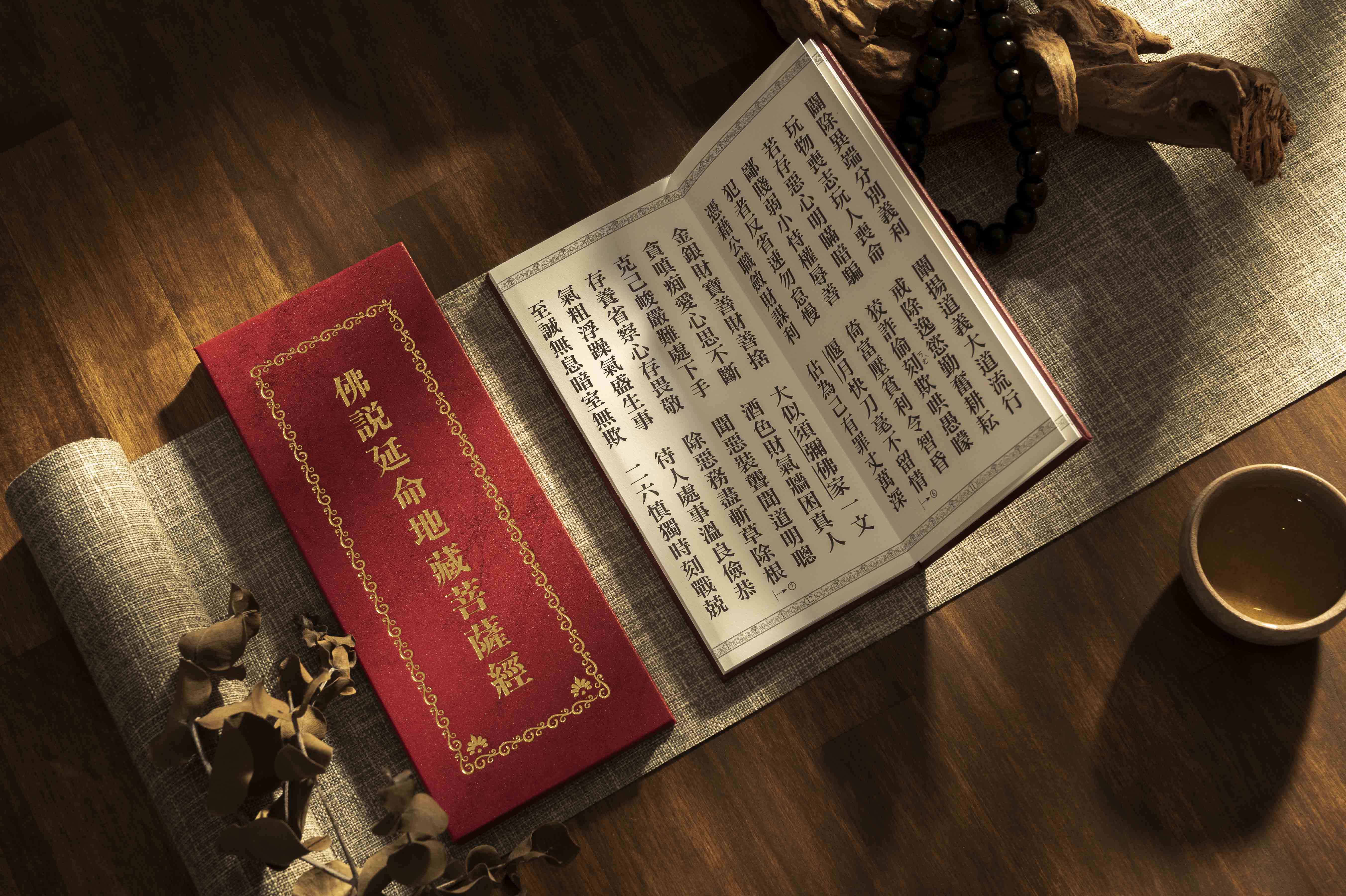

The hot stamping, also known as foil stamping, is a printing technique that uses heat, pressure, and metallic or pigmented foils to create a shiny, decorative effect on a variety of materials. This method is often used to enhance the appearance of printed products, adding a luxurious and premium finish.

|

|

(下)封面.jpg) |

|

|

|

Process of Hot Stamping

|

Types of Foils Used in Hot Stamping1. Metallic Foils:- Gold, silver, bronze, and other metallic colors. - Create a shiny, reflective finish. 2. Pigmented Foils:- Solid colors without metallic sheen. - Provide a flat, opaque finish. 3. Holographic Foils:- Contain patterns that create a holographic effect. - Used for security purposes or decorative designs. 4. Specialty Foils:- Pearl, matte, or glossy finishes. - Offer unique textures and appearances. |

Advantages of Hot Stamping1. High-Quality Finish:- Produces a crisp, clean, and professional look. - Adds a touch of elegance and sophistication. 2. Durability:- Foil stamping is resistant to fading and wear. - Maintains its appearance over time. 3. Versatility:- Can be applied to various materials, including paper, cardboard, leather, and plastics. - Suitable for a wide range of products, such as business cards, book covers, packaging, and labels. 4. Customization:- Allows for intricate designs and fine details. - Offers a variety of foil colors and finishes. |

Limitations of Hot Stamping1. Cost: - Initial setup costs can be high due to the need for custom dies. - More expensive than some other printing methods.

2. Time-Consuming: - The process can be slower than digital printing, especially for short runs.

3. Complexity: - Requires precise control of heat and pressure for optimal results. - Not suitable for all types of materials or designs. |

Applications of Hot Stamping1. Packaging: - Enhances the appearance of product packaging, such as boxes and bags.

2. Stationery: - Adds a luxurious touch to wedding invitations, business cards, and greeting cards.

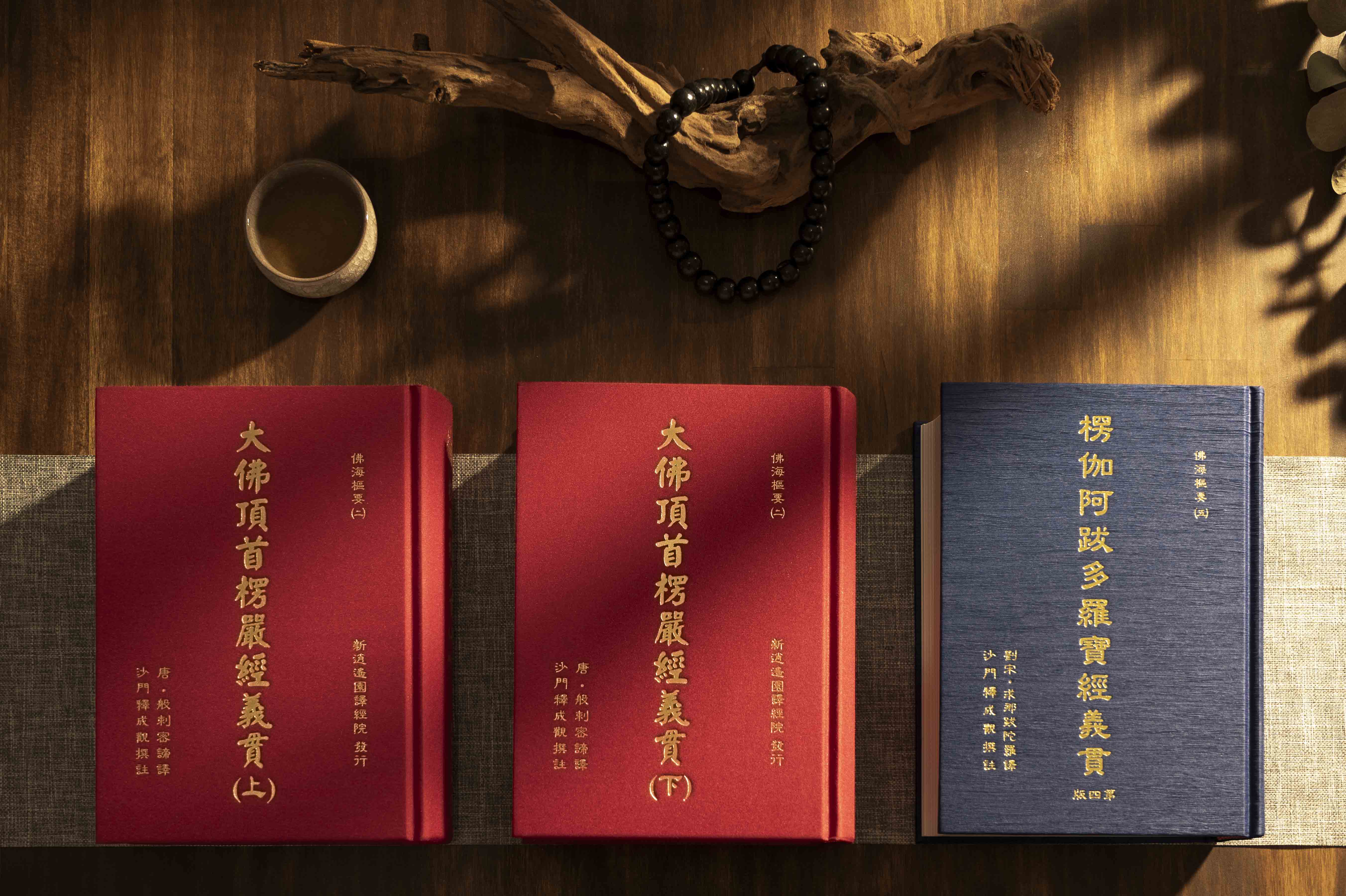

3. Books: - Used for book covers, spines, and special editions.

4. Labels: - Applied to labels for high-end products, like cosmetics and wine bottles. |

Conclusion

Hot stamping is a versatile and effective printing technique that adds a premium, eye-catching finish to a variety of products. While it may involve higher costs and more complex setup compared to other methods, the durability and aesthetic appeal it offers make it a popular choice for many high-end and decorative applications.

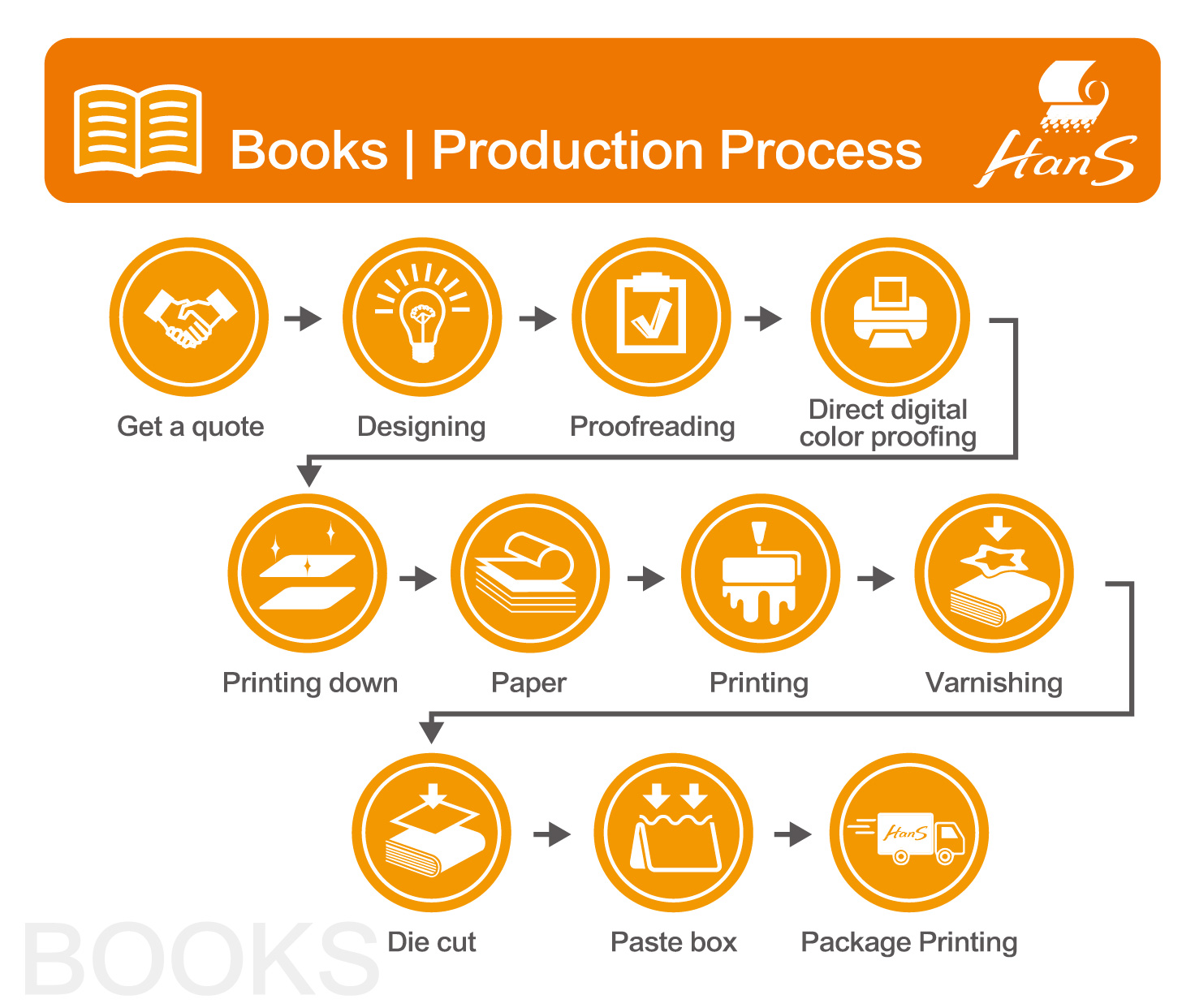

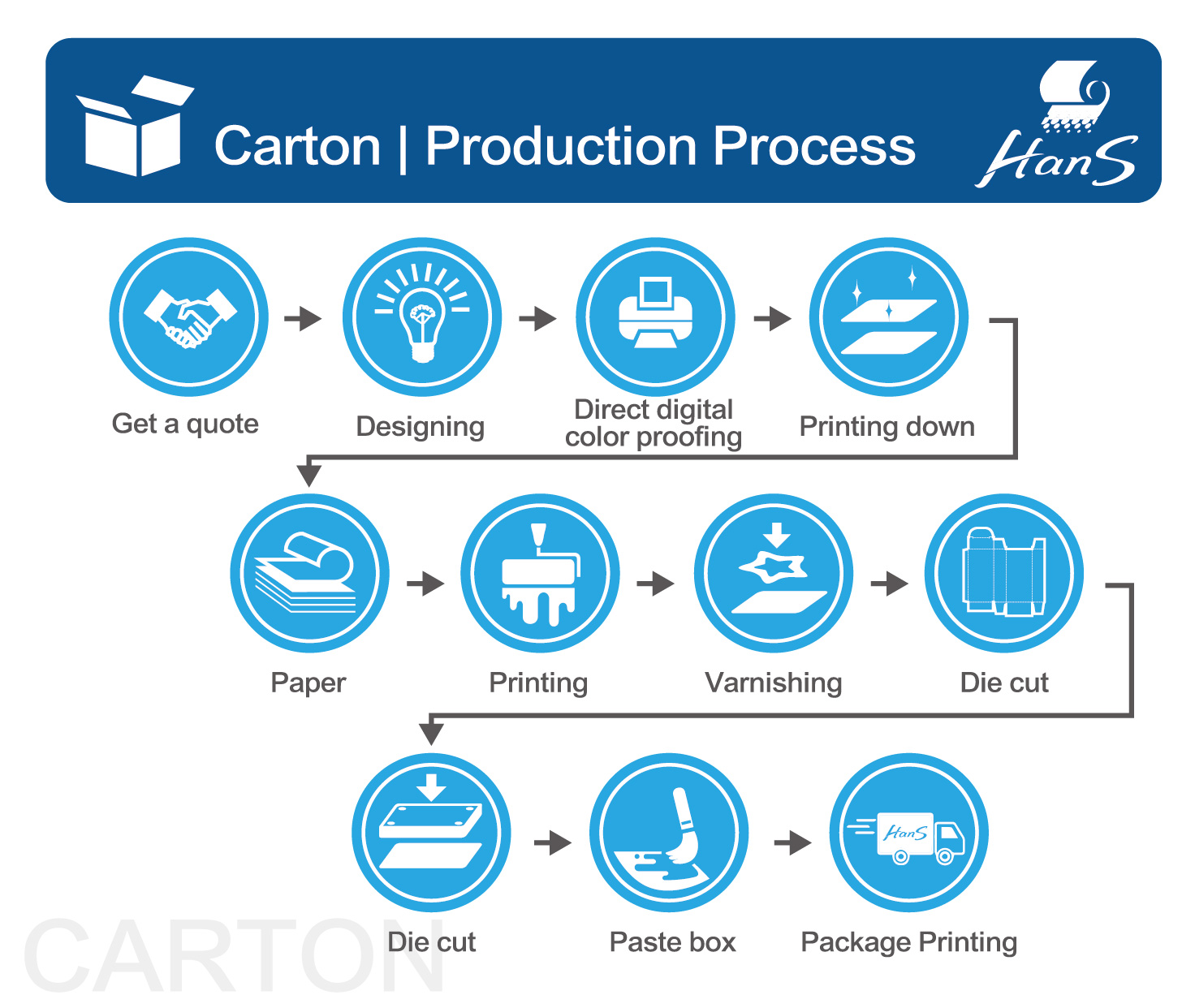

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.