Printing Process

-

sentiment_very_satisfied

Viewers:

- 0

The 3 Steps of the Printing Process

What are the steps of the printing process? We're glad you asked!

There are three primary stages of commercial printing: prepress, press, and post press. In this section, we'll explain each step in detail so you can better understand how the print process works.

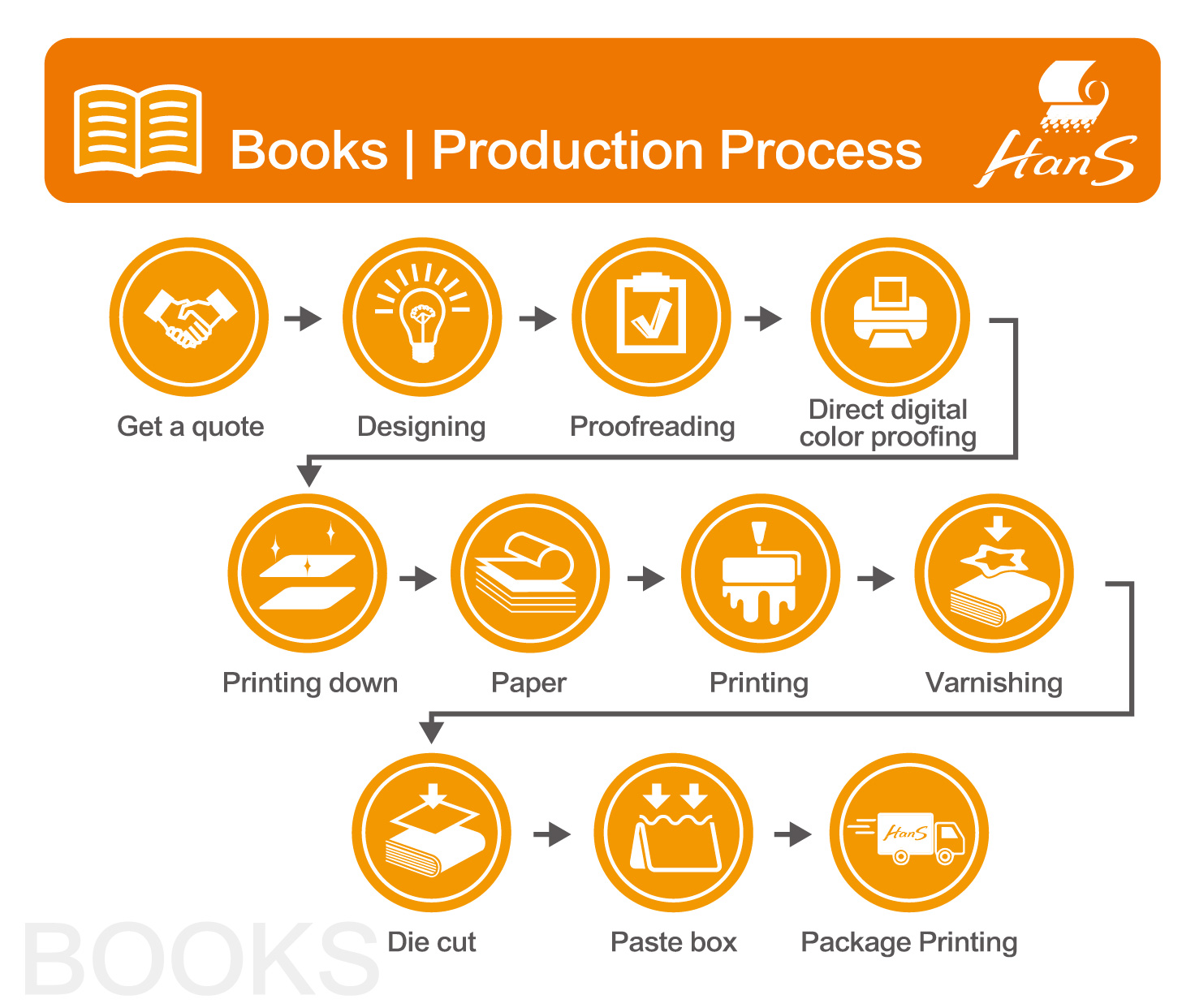

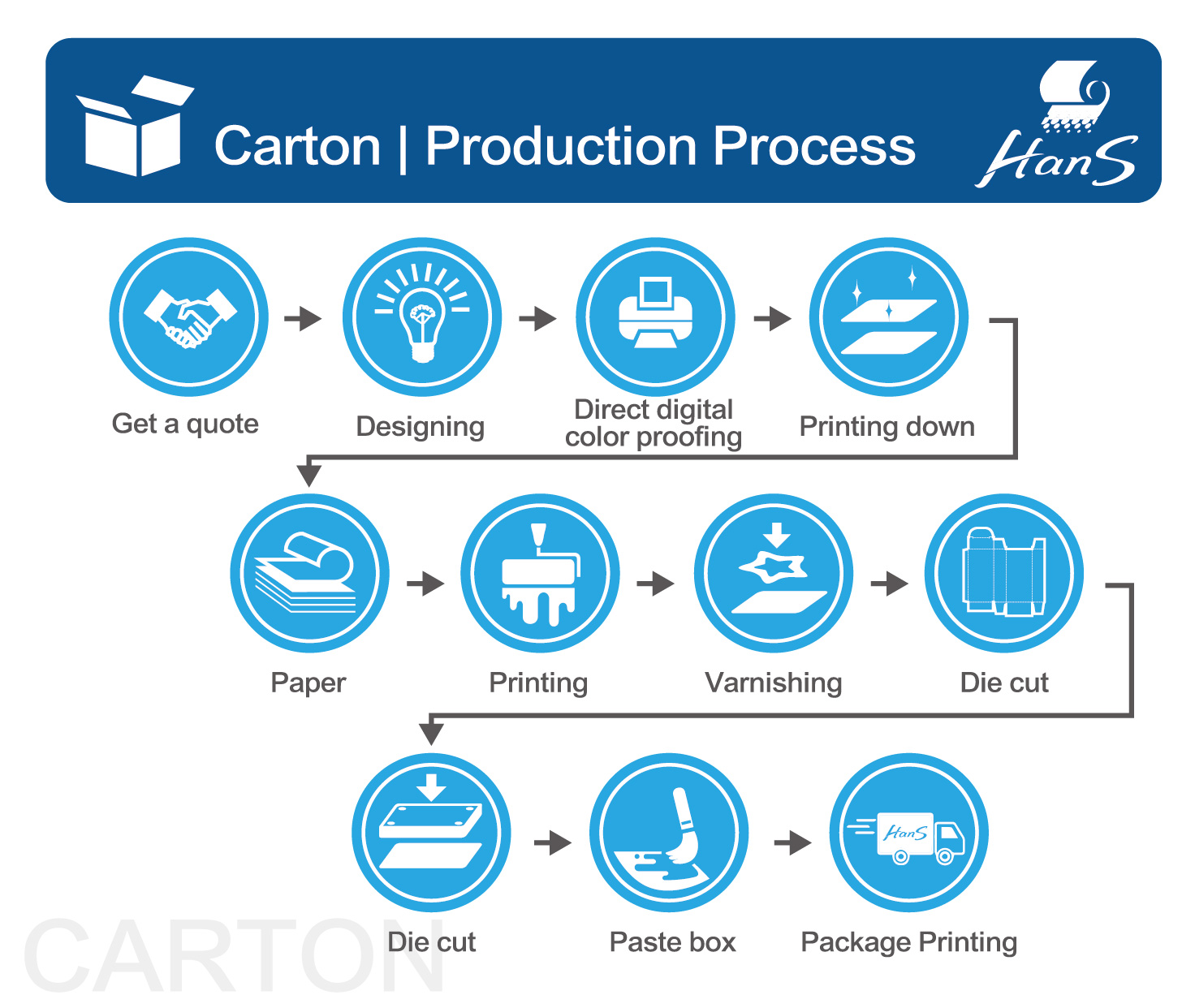

1. PrepressPrepress is the first step of the commercial printing process, and it's where all the planning and preparation occur. Most of the prepress steps are done via computer.

This step includes composition, typesetting, graphic arts photography, formatting files according to industry standards, and image assembly. These prepress operations prepare the concept for a printed image to be converted into an image carrier, such as a plate, cylinder, or screen.

The steps also involve converting digital files into a form that the press can understand and using software to prepare the files for printing. During the prepress step, proofing for errors and more is also done to ensure everything looks perfect before printing. The result should be an accurate representation of what the final product will look like once printed. |

|

2. PressOnce the prepress steps have been completed, it's time to move on to the press stage, where the actual printing process occurs. This phase involves setting up the presses and printing the image onto a substrate (such as paper or plastic), using either an offset printing press or a digital press.

For each job, the specific press setup is dependent on the type of substrate being used. For example, you might need to use a different printing plate or ink colors than usual in order to achieve the desired effect on certain materials. During this phase, it's also important to make sure everything is correctly aligned, as any misalignments or shifts in color can ruin an entire print run. |

3. Post PressOnce the printing is complete, it's time to move on to the post press phase. This stage involves operations such as trimming, folding, scoring, and binding. It includes finishing processes like embossing, die-cutting, varnishing, laminating, and more. These processes achieve a certain look or feel, such as a glossy finish or special shape. |

Lastly, post press operations involve packaging the printed materials for shipping or storing them until they're ready for distribution. This stage is about making sure your prints arrive in pristine condition, and that they look exactly the way you intended them to.

Which Printing Process Is Most Commonly Used for Commercial Printing?

|

A few of the most popular printing processes for commercial projects are direct-to-press printing, digital printing, lithography, flexography, and screen printing. However, the most popular option for commercial printing is offset printing, also known as lithography printing.

Lithography printers are printing presses that use a series of cylinders to transfer an image onto paper or other substrates. It is widely used in the industry for its ability to produce high-quality prints in large volumes more quickly and cost-effectively than other processes. Common applications for lithography printing include magazines, brochures, stationery and sell sheets.

Digital presses are also gaining popularity due to their efficiency, affordability, and flexibility. This type of printing is used for short-run projects or those with frequent updates. |

|

Industries That Use Commercial Printing Services

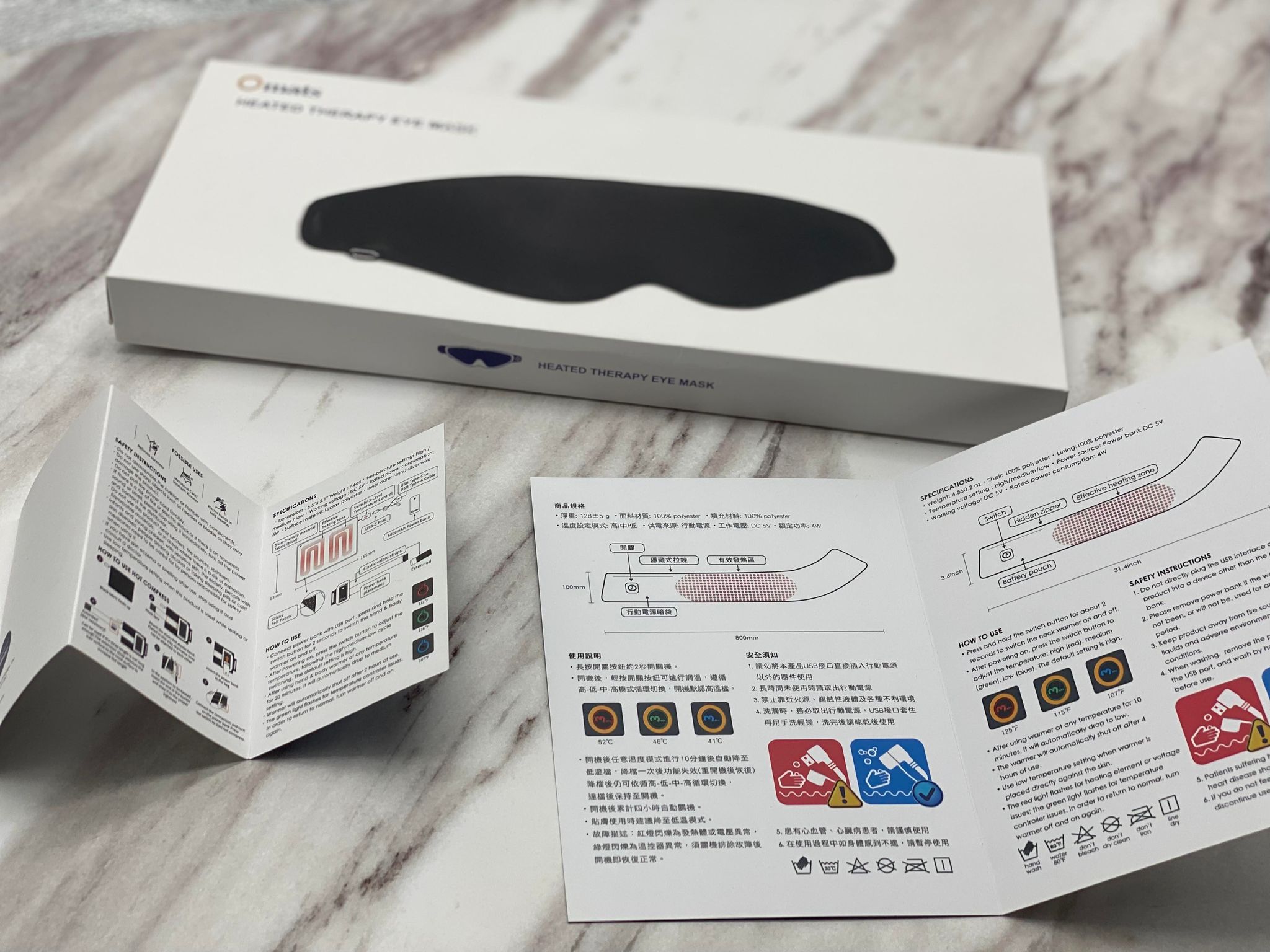

Commercial printing is used in various industries, including publishing, advertising and marketing, retail packaging, product labels, signage and banners, and more.

The creative possibilities offered by commercial printing make it invaluable for businesses that need to produce high-quality printed materials quickly. It's especially useful for those who want to make their products stand.

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.