Color Printing Plate

-

sentiment_very_satisfied

Viewers:

- 0

Color printed plate involves printing designs, patterns, or images directly onto the surface of plywood sheets.

|

|

Color Printing on Plate Process |

1. Plate Preparation- Sanding: The Plate surface is sanded to ensure it is smooth and free from imperfections. This step is crucial for achieving a high-quality print. - Priming: Sometimes, a primer is applied to the plywood to enhance the adhesion of the ink and improve color vibrancy. |

2. Design Preparation- Digital Design: The design is created or adapted using graphic design software. This can include patterns, images, logos, or any other visual elements. - Color Matching: Colors are adjusted to match the desired output, taking into account the natural color and texture of the plate. |

3. Printing Technology- UV Printing: Ultraviolet (UV) printing is commonly used for printing on plate. UV printers use UV light to cure the ink as it is printed, resulting in a durable and high-quality finish. - Direct-to-Substrate Printing: This method involves printing directly onto the plate surface without the need for transfer paper or additional layers. - Screen Printing: For large-scale or repetitive patterns, screen printing can be used. This involves creating a stencil (screen) and using it to apply layers of ink onto the plate. |

4. Printing Process- Loading: The plate sheet is loaded onto the printer bed. - Printing: The printer applies the ink directly onto the plate surface according to the digital design. - Curing: If UV printing is used, the UV light cures the ink immediately, making the print durable and resistant to smudging or scratching. |

5. Finishing- Sealing: A clear sealant or varnish may be applied to protect the printed design and enhance its longevity. - Cutting and Shaping: The printed plate can be cut and shaped according to the required dimensions for its final application. |

Applications of Color Printed Plate |

1. Furniture- Custom designs on tables, chairs, cabinets, and other furniture pieces. - Personalization of furniture with logos, images, or unique patterns. |

2. Interior Design- Decorative wall panels and ceiling tiles. - Custom flooring with intricate designs. - Artistic installations and feature walls. |

3. Signage- Custom signs for businesses, events, or home decor. - Branding elements for stores and exhibitions. |

4. Architectural Elements- Unique facades and decorative exterior panels. - Custom room dividers and partitions. |

5. Art and Craft- Artistic pieces and custom artworks on plate canvases. - Personalized gifts and home decor items. |

Advantages of Color Printed Plate |

1. Durability- UV-cured prints are resistant to fading, scratching, and wear, making them suitable for high-traffic areas and outdoor use. |

2. Customization- Allows for high levels of customization with precise color matching and intricate designs. |

3. Aesthetic Appeal- Combines the natural texture and warmth of wood with vibrant, detailed prints, offering a unique visual appeal. |

4. Cost-Effective- Printing directly on plate can be more cost-effective than other decorative techniques, especially for large-scale projects. |

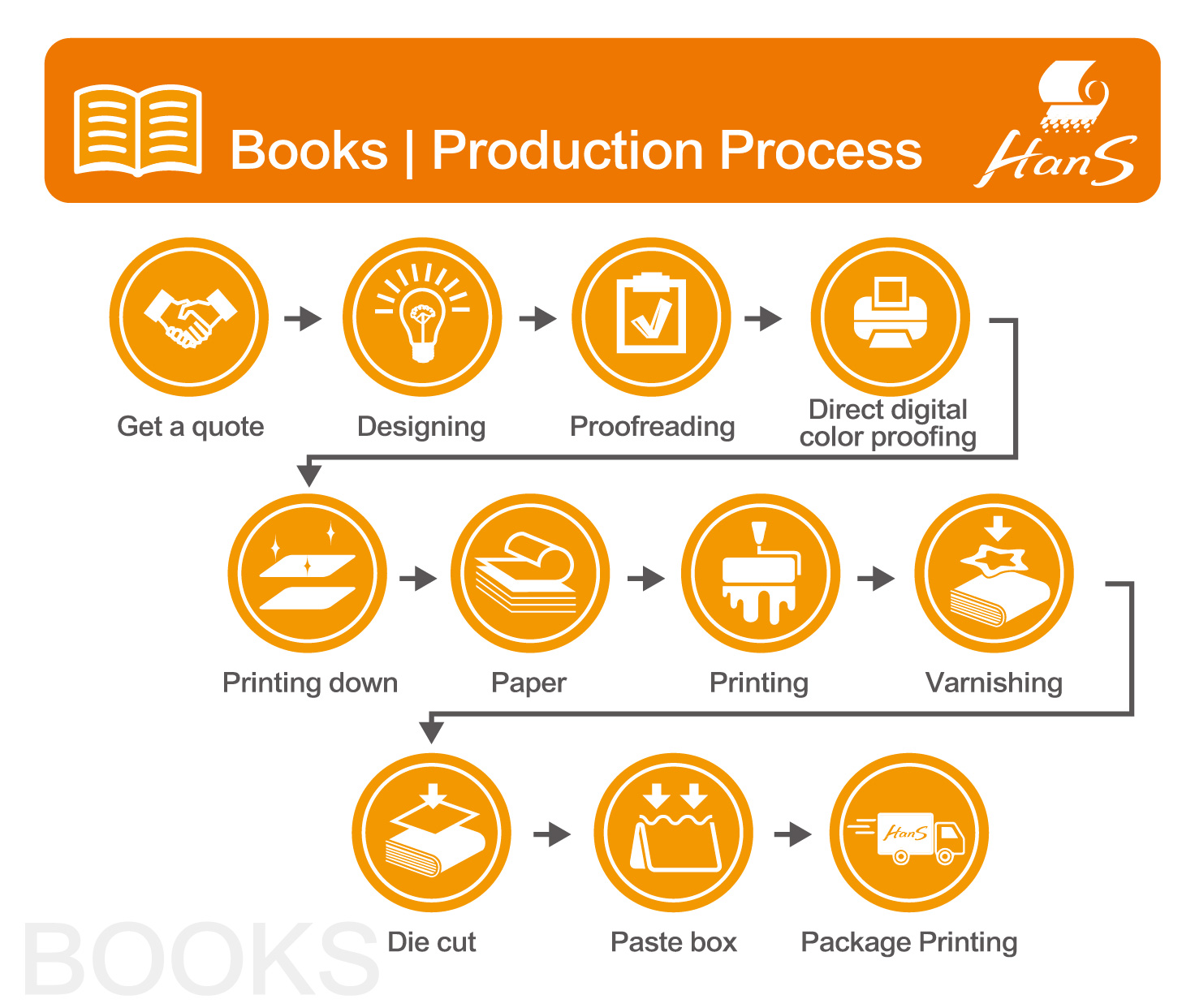

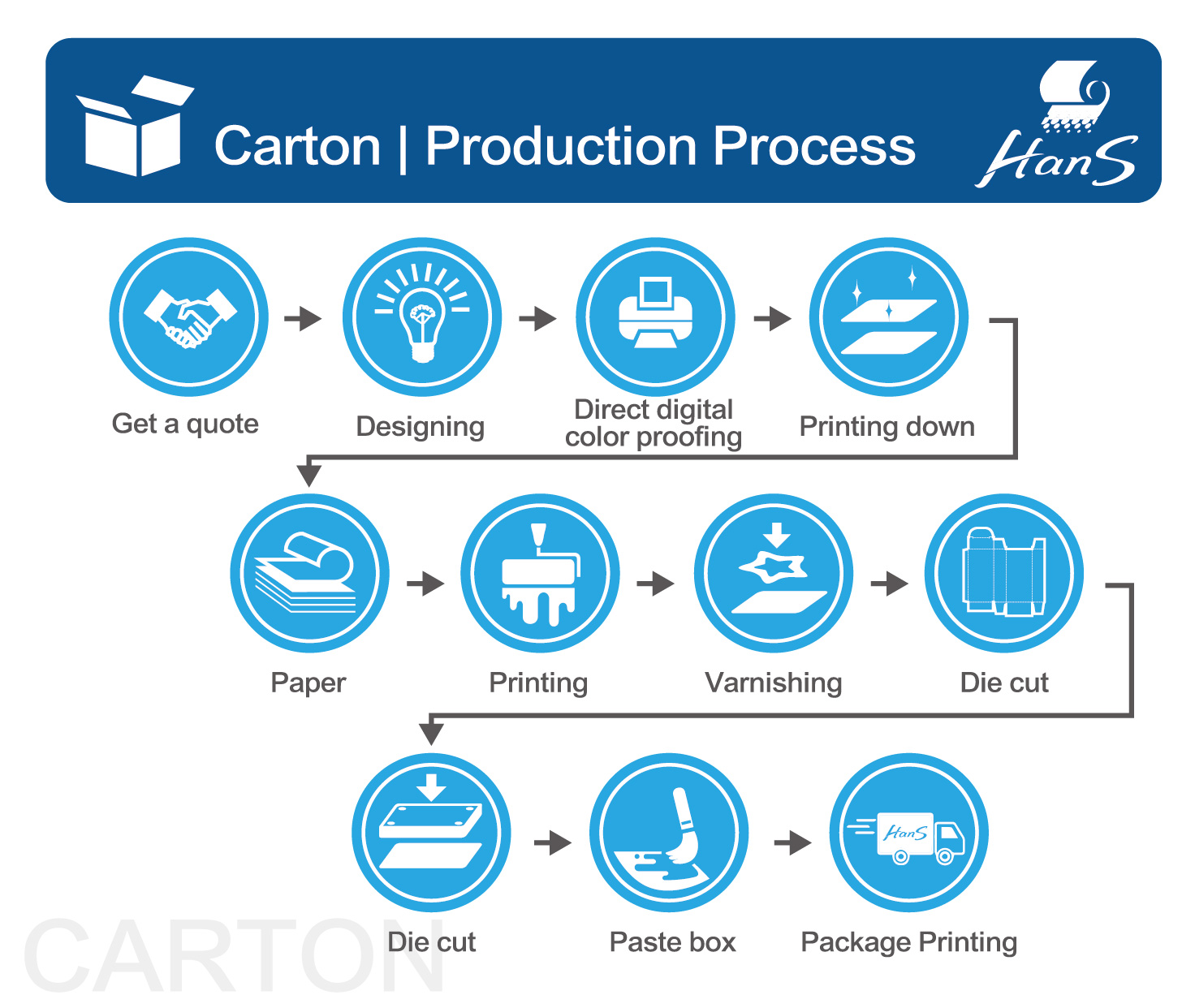

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.