Custom Box Packaging Product

-

sentiment_very_satisfied

Viewers:

- 342

Custom box packaging product box printing wholesale, Custom box packaging product box printing usa, Custom box packaging product box printing price, Custom box packaging product box printing online, Custom box packaging product box printing near me

Design and Specifications

1.Product Requirements: Determine the dimensions, shape, and weight capacity the box needs to accommodate.

2.Brand and Graphics: Integrate brand elements such as logos, colors, and information to reflect the product or company's identity.

3.Structural Design: Design the box to ensure it is sufficiently sturdy to protect the product during transportation and handling.

Material Selection

1. Box Material: Choose appropriate materials based on durability, eco- friendliness (such as recyclability), and aesthetic appeal, like matte or glossy finishes.

2. Printing Methods: Select printing techniques such as offset printing, digital printing, or screen printing based on design complexity and production volume.

Prototype Making and Testing

1. Sample Production: Produce samples to test and ensure the box design meets product requirements and is correctly assembled.

2. Quality Assurance: Conduct tests for durability, stacking strength, and resistance to external factors like moisture or impact to ensure product quality and stability.

Production and Manufacturing

1. Production Process: Once the design and materials are finalized, use specialized equipment and machinery for large-scale production.

2. Processing Options: Consider additional processing options such as embossing, debossing, printing enhancements, or laminating to enhance visual appeal.

Packaging and Assembly

1. Assembly Line: Implement an efficient assembly process to ensure accurate folding, gluing, and assembly of the boxes.

2. Inserts and Fillers: Include inserts or fillers inside the box as needed to secure the product and prevent movement during transportation.

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.

content related to paper box printing production:

- Size Format: Dimensions of the paper box in length x width x height in centimeters.

- Paper Types: Single copperplate, gray copper card, drill card paper, watermarked white card paper, white copper card paper, copper west card paper, art paper (imported paper).

- Mounting Corrugated Paper: Mounting E wave, mounting white E wave, mounting B wave, mounting F wave, mounting kraft paper, mounting E wave + B wave.

- Paper Thickness: Paper thickness (250 pounds, 300 pounds, 350 pounds, 400 pounds, 500 pounds, 600 pounds).

- Printing Colors: Six-color printing, five-color printing, four-color printing, two-color printing, monochrome printing.

- Printing Quantity: Quantity.

- Sampling Method: Digital sampling or formal sampling (direct machine printing sampling or sampling).

- Die Cutting Types: General die cutting, Japanese die cutting, Swiss die cutting, steel die cutting, laser die cutting, metal die cutting.

- Box Surface Treatment: Water-based gloss, gloss, matte, suede, frosted, matt, or partial gloss, UV gloss (UV is divided into gloss UV, frosted UV, release UV).

- Special Techniques: Skylight, hand-held handle, transparent film pasting, hot stamping gold and silver, copper button pressing.

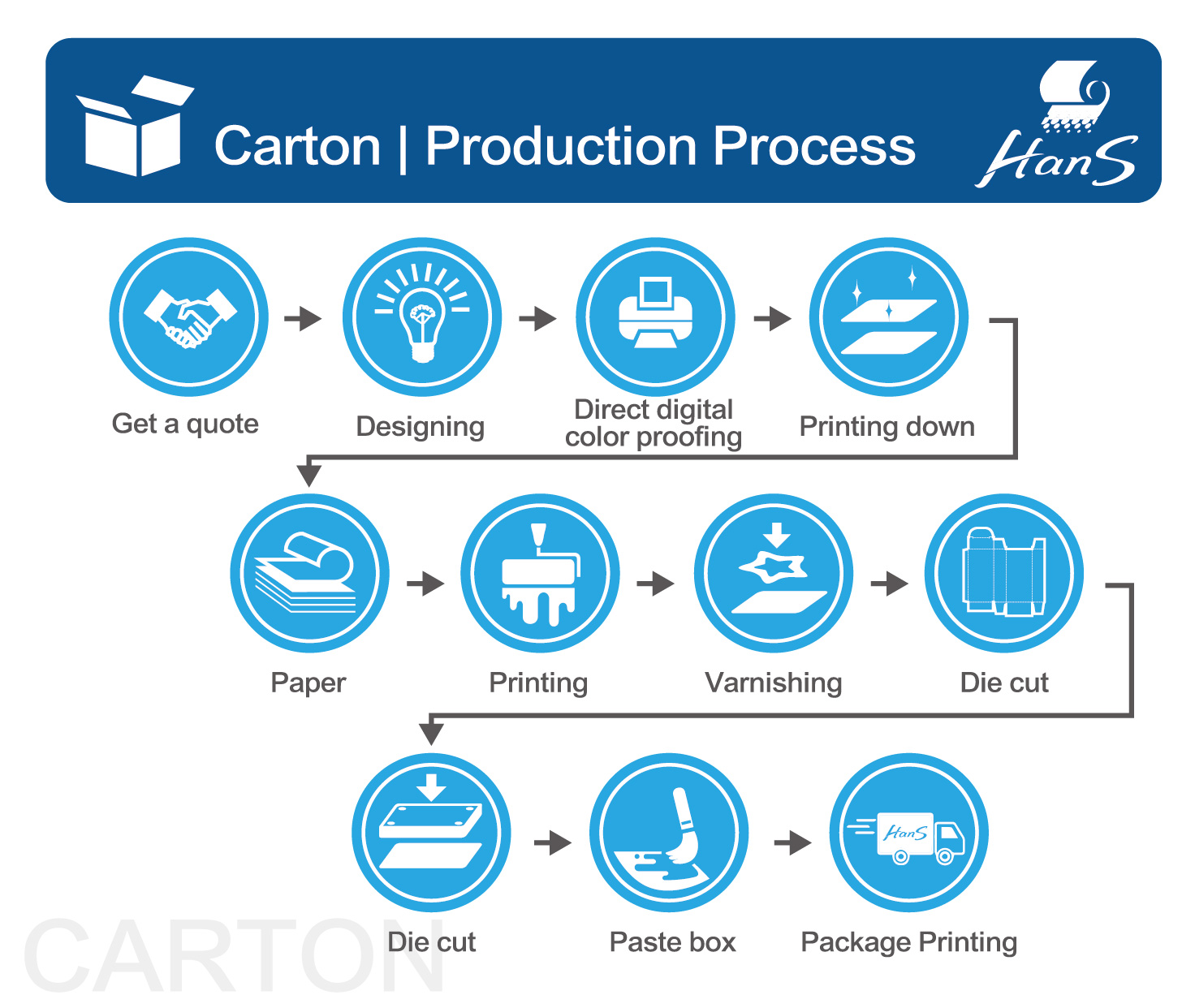

The paper boxes printing production process:

Quotation and contract signing ==> Design ==> Final draft editing ==> Proofreading ==> Digital sample printing (for formal sample) ==> Paper printing ==> Mounting on corrugated board ==> Plate exposure ==> Printing ==> Glossing ==> Die cutting ==> Assembly ==> Handmade box ==> Packaging and shipping (1-month process)

, Custom product boxes, Custom box packaging product box printing wholesale usa, Custom box packaging product box printing wholesale near me, Custom box packaging product box printing wholesale price, Custom product boxes.Custom boxes with logo wholesale, Custom packaging boxes with logo, Custom printed boxes.Custom printed boxes no minimum