Saddle Stitch Printing

-

sentiment_very_satisfied

Viewers:

- 399

Saddle stitch printing near me, How to print saddle stitch booklet, Saddle stitch binding, Saddle Stitch booklet template, Saddle stitch booklet machine, Saddle stitch booklet page count, Saddle stitch bookbinding

- Custom Saddle Stitch Printing

Saddle stitch booklet printing is a popular choice for creating versatile and affordable booklets. Whether you're producing brochures, catalogs, event programs, or instructional manuals, saddle stitch binding offers several advantages:

- Cost-Effective Production

- One of the primary benefits of saddle stitch booklets is their cost-effectiveness. The production process is relatively simple compared to other binding methods, such as perfect binding or spiral binding. This simplicity translates to lower manufacturing costs, making saddle stitch booklets a budget-friendly option for large quantities.

- Professional Appearance

- Despite its affordability, saddle stitch binding provides a professional and polished look to your booklets. The pages are neatly folded and stapled together along the spine, giving the booklet a sleek finish. This makes saddle stitch booklets suitable for a wide range of uses, from marketing materials to informational handouts.

- Versatility in Design

- Saddle stitch booklets are versatile in terms of design and layout. You can choose from various paper weights and finishes to achieve the desired look and feel for your booklet. Whether you prefer glossy or matte paper, the flexibility in paper selection allows you to customize the booklet to match your brand or project requirements.

- Suitable for Different Sizes

- Another advantage of saddle stitch binding is its suitability for different booklet sizes. Whether you need a small pocket-sized booklet or a larger manual, saddle stitch binding can accommodate various dimensions. This flexibility makes it easier to create booklets that are convenient and practical for your intended audience.

- Quick Turnaround Time

- If you're working with tight deadlines, saddle stitch booklets offer a quick turnaround time. The binding process is efficient, and once the pages are printed and folded, they can be stapled together swiftly. This means you can produce booklets in large quantities within a short timeframe, ideal for urgent projects or last-minute printing needs.

- Eco-Friendly Option

- For environmentally conscious businesses and organizations, saddle stitch booklets can be a sustainable choice. Many printing companies offer eco-friendly paper options and use processes that minimize waste. Additionally, the simplicity of saddle stitch binding reduces the use of adhesives or other materials that may not be recyclable.

- Ideal for Medium-Length Documents

- While saddle stitch binding is suitable for various booklet sizes, it is particularly well-suited for medium-length documents. Booklets with a moderate number of pages (typically up to 64 pages, depending on paper thickness) benefit most from saddle stitch binding. This binding method ensures that the booklet lies flat when opened and allows for easy reading and handling.

In conclusion, saddle stitch booklet printing combines affordability with versatility, making it a popular choice for many printing projects. Whether you're looking to create promotional materials, instructional guides, or event programs, saddle stitch booklets offer a professional finish and practicality that meet a wide range of needs.

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.

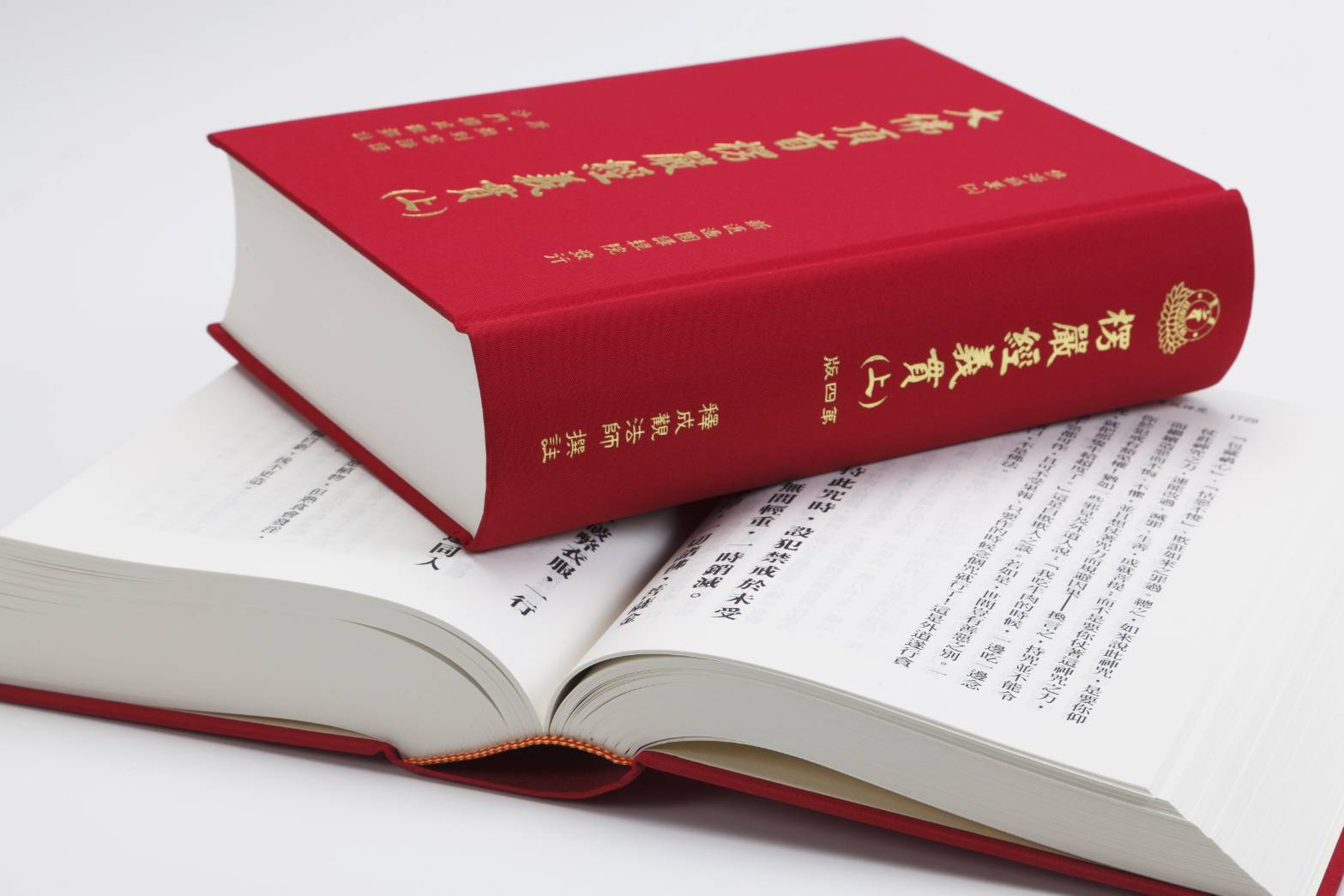

The content related to Books Printing production :

- Size Limitation : Min. 36.5x54.4cm, Max. 72x102.4cm

- Available paper of books cover: Mold-made paper, Wood-free paper, Gloss coated art paper, Matt art paper, Coated post card or other imported paper.

- Available paper of books interior pages: Mold-made paper, Wood-free paper, Magazine paper, Gloss coated art paper, Matt art paper, Bit-coated woodfree, News paper.

- Paper Weight of books Cover: 80gsm, 100gsm, 120gsm, 150gsm, 180gsm, 200gsm.

- Interior Page Paper Weight: 60gsm, 70gsm, 80gsm,100gsm, 120gsm, 150gsm.

- Available size of books cover: B4, B5, B6, A3, A4, A5, A6.

- Color: 6 color process printing, 5 color process printing, 4 color process printing, 2 color process printing, Single color process printing are available.

- Varnishing of books cover: Aqueous coating, Poly propylene coating, Matte pp coating, Flannel coating, Frosted coating, Spot varnish and ultra violet coating (include gloss UV, matte UV, release UV).

- Binding options: Half-fold, S fold, 3~4 panel fold, 5~12 panel fold, Gate fold, Saddle stitched, Perfect bound, Thread sewn glued, Hot stamping.

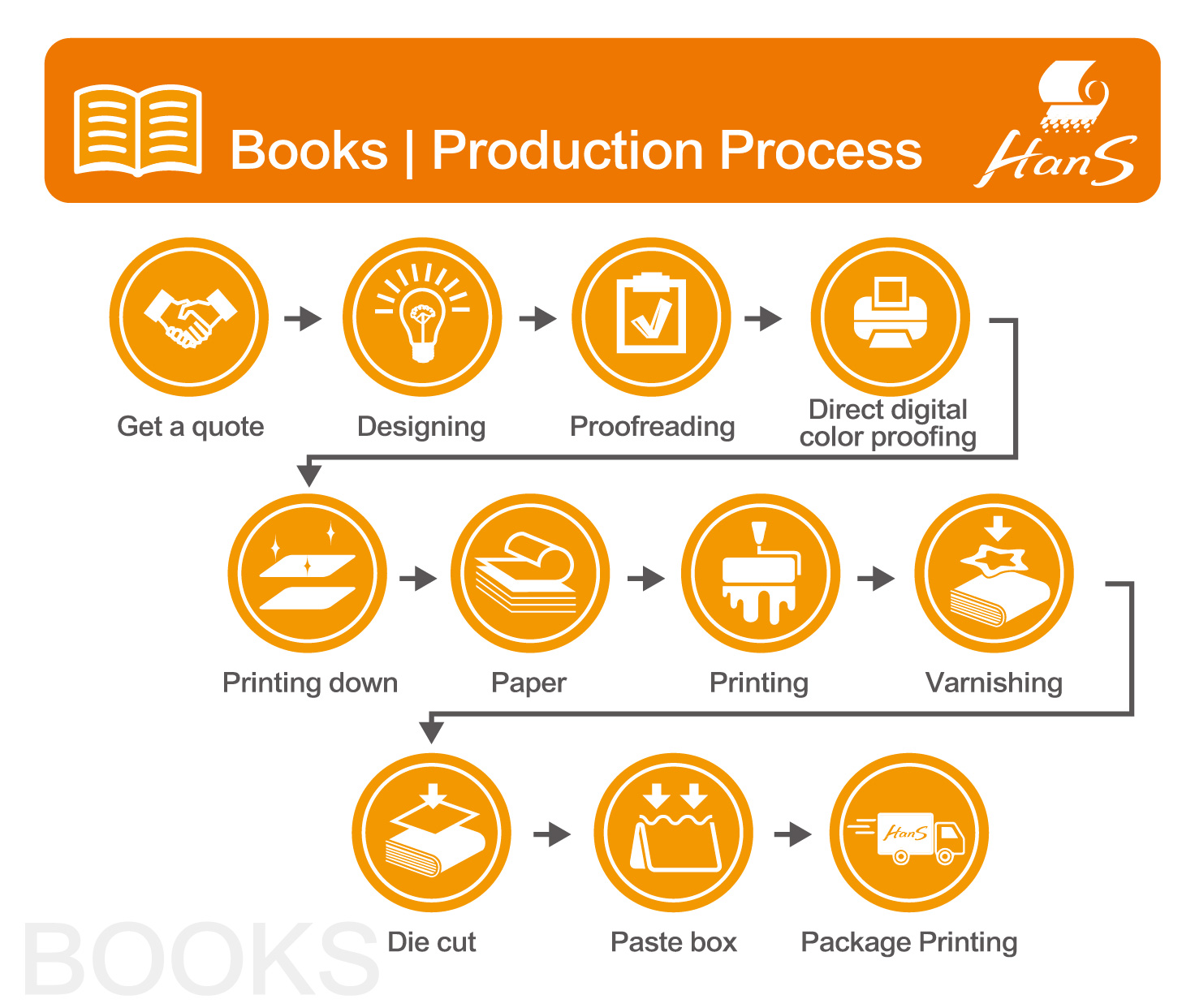

Book printing production process :

Quotation and transaction contract==>Printing and providing files(Illustrator/ Photoshop / CorelDraw/ InDesign/ PDF)==>Printing digital samples==>Printing paper ==> Plate exposure ==>Printing ==>Glazing ==>Binding ==>Packing and shipping(1-month process)