Boxes Professional Printing

-

sentiment_very_satisfied

Viewers:

- 434

Boxes professional printing near me.Custom printed boxes.Custom printed boxes no minimum.Custom packaging boxes with logo.Custom boxes.Custom boxes with logo wholesale.Custom product boxes.Custom box design

The box printing is the process of producing printed designs on boxes used for packaging products.

This process involves various printing methods and techniques to achieve high-quality results that meet the specific needs of brands and businesses, not only ensures the visual appeal of the packaging but also includes considerations for durability, functionality, and sustainability.

|

|

|

|

|

Gable Gift Boxes • Gable boxes or handled boxes, are typically made of cardboard or paperboard. • Easy to Carry Built-in handle. • Lightweight single piece flat-pack construction. |

Product Boxes • Custom designs, logos, and information can be printed on boxes. • Are perfect for individual product packaging and lightweight items. • Bring it to life with custom printed designs inside and out.

|

Gift Box with Rope Handles • The rope handle is usually providing a comfortable grip and enhancing the box's aesthetic appeal. • Available in various shapes and sizes, often rectangular or square, to accommodate different gift items. |

»Types of Box Printing :

| Offset Printing | Digital Printing | Flexographic Printing |

|

- Is a traditional printing method that uses plates to transfer ink onto the packaging material. - This method is known for its high-quality results and is ideal for large print runs due to its cost-effectiveness. |

- Is a modern technique that uses digital files to print directly onto the packaging material. - This method is suitable for short print runs and offers flexibility, quick turnaround times, and the ability to easily make changes to the design. |

- Uses flexible plates to transfer ink onto the packaging material. - It is commonly used for printing on corrugated boxes, plastic bags, and other flexible substrates. - Flexo printing is known for its speed and efficiency, making it ideal for large volumes and continuous runs. |

»Choosing the Right Printing Method for Boxes

| - Factors to Consider | - Cost Implications | - Quality Comparison |

|

Several factors need to be considered, including the print run size, desired quality, budget, and the type of material being used.

Each printing method has its own advantages and limitations. |

Offset printing is typically more economical for large quantities, while digital printing is cost-effective for smaller runs.

Flexographic printing offers a balance between cost and quality, especially for high-volume orders. |

Offset printing is superior print quality and color accuracy.

Digital printing, while slightly lower in quality, has advanced significantly and is suitable for most applications.

Flexographic printing offers good quality but may not achieve the same level of detail as offset printing. |

|

|

|

|

»Preparing Your Design for Box Printing

| - Design Guidelines | - Choosing Materials | - Finishing Options |

|

Preparing your design for box printing involves following specific guidelines to ensure the final product meets your expectations.

This includes setting the correct dimensions, resolution, and color profiles.

It's also important to consider the placement of text and images to avoid any issues during the printing and cutting process. |

The choice of materials can significantly impact the appearance and durability of the printed boxes.

Common materials include corrugated cardboard, paperboard, and plastic.

Each material has its own properties and is suited to different types of products and printing methods. |

Finishing options, such as gloss or matte coatings, embossing, and lamination, can enhance the look and feel of the printed boxes.

These options not only improve the aesthetic appeal but also provide additional protection and durability. |

|

|

|

|

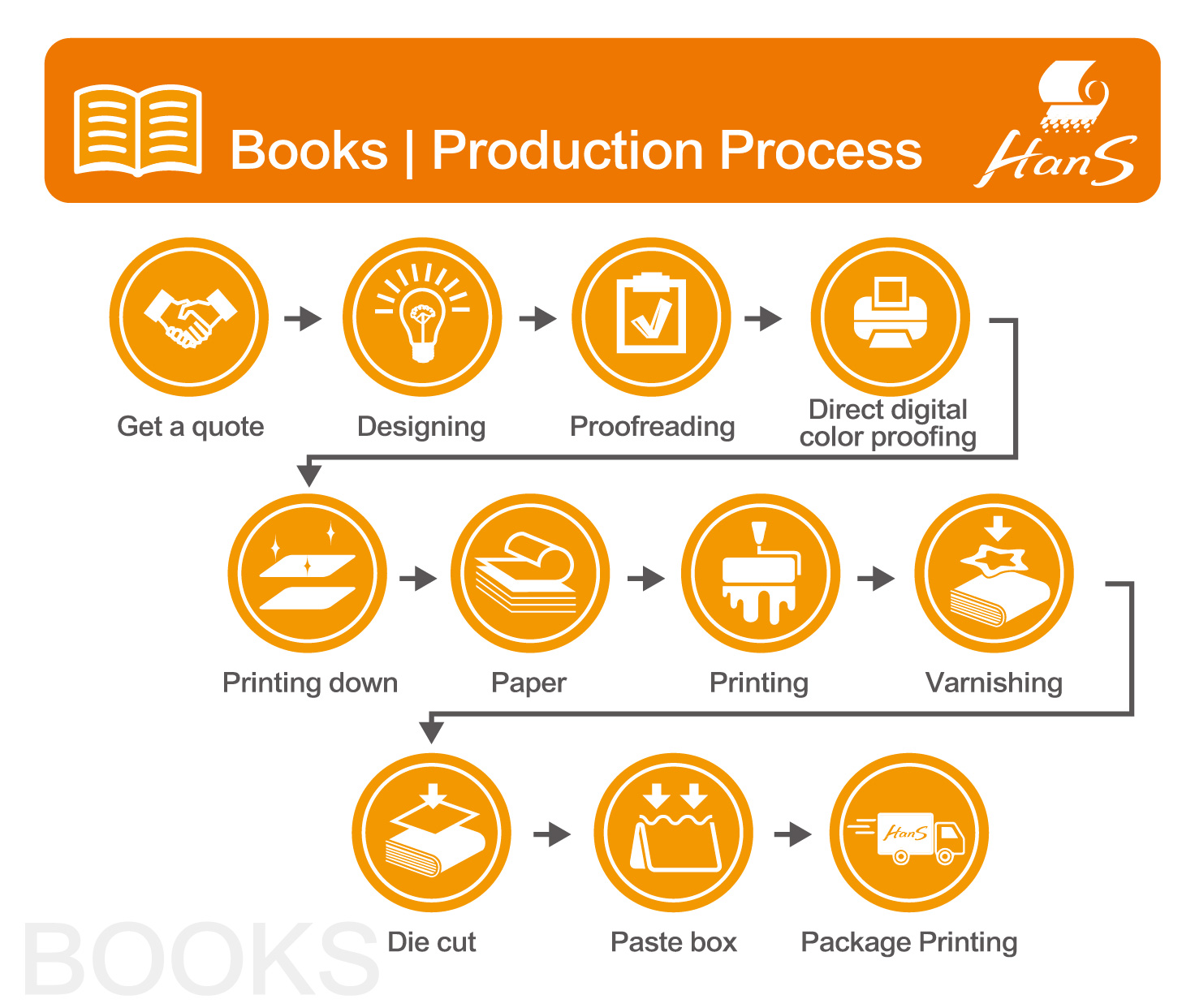

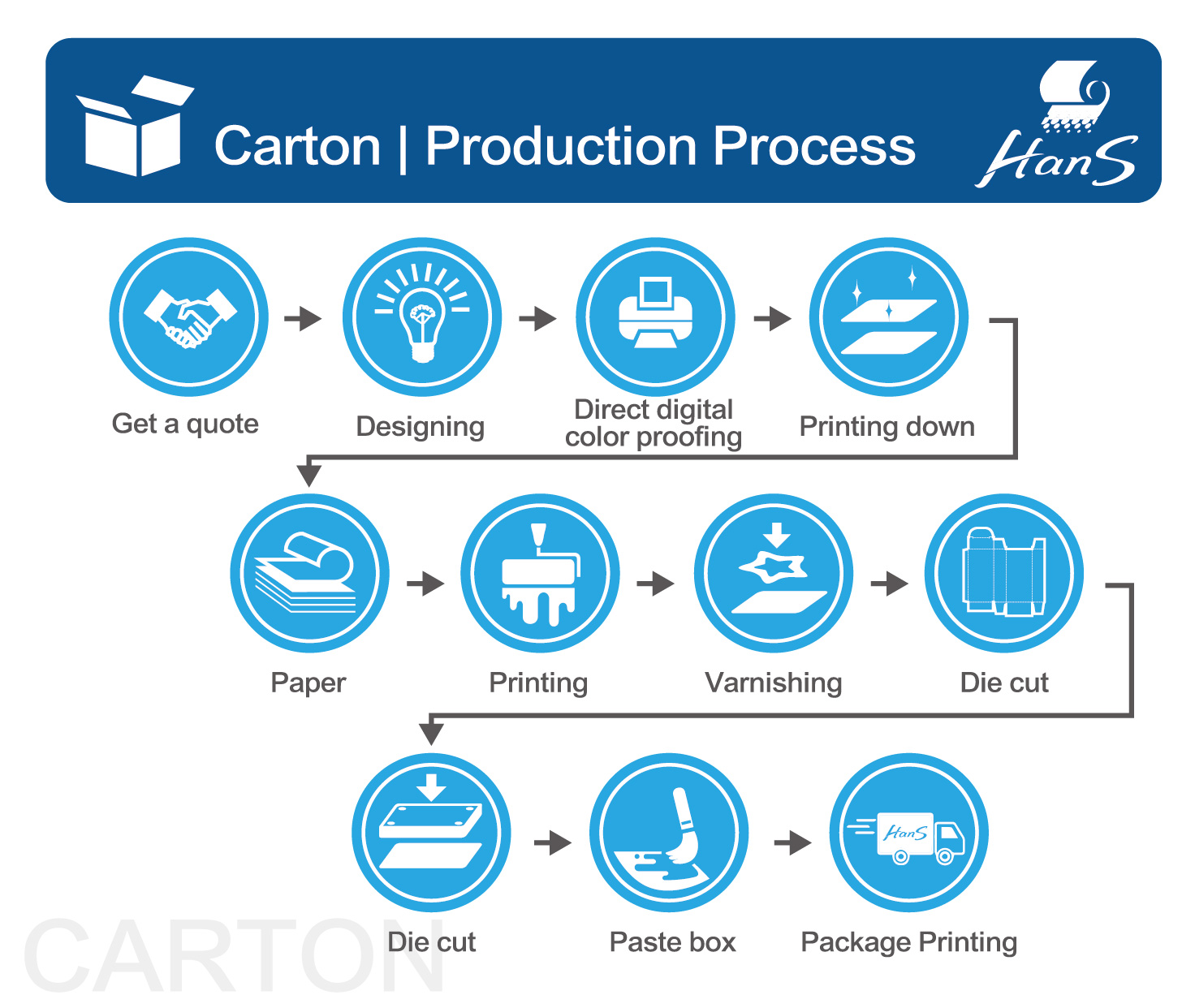

»Printing Process for Boxes Explained

| - Prepress | - Printing | - Cutting and Folding | - Assembling |

|

The prepress stage involves preparing the design files for printing.

This includes checking for errors, making necessary adjustments, and creating printing plates or digital files.

Proper prepress preparation is crucial for achieving high-quality results. |

The printing stage involves transferring the design onto the packaging material.

Depending on the chosen method, this can involve using plates, digital printers, or flexographic presses.

Each method has its own set of procedures and equipment. |

After printing, the packaging material is cut and folded into the desired shape.

This stage requires precision to ensure that the boxes are accurately formed and ready for assembly. |

The final stage involves assembling the printed boxes into their finished form.

This can include gluing, taping, or other methods of securing the boxes.

Proper assembly ensures that the boxes are sturdy and ready for use. |

»Quality Control in Box Printing

| - Common Quality Issues | - Quality Assurance Techniques | - Maintaining Consistency |

|

Common quality issues in box printing include color inconsistencies, misaligned text, and cutting errors.

Identifying these issues early can help prevent costly reprints and ensure a high-quality final product. |

Quality assurance techniques include proofing, checking print samples, and conducting regular inspections throughout the printing process.

Working with a reputable printer can also help maintain high standards. |

Consistency is key in box printing, especially for large print runs.

Establishing clear communication with your printer and setting quality standards can help maintain consistency throughout the production process. |

|

|

|

|

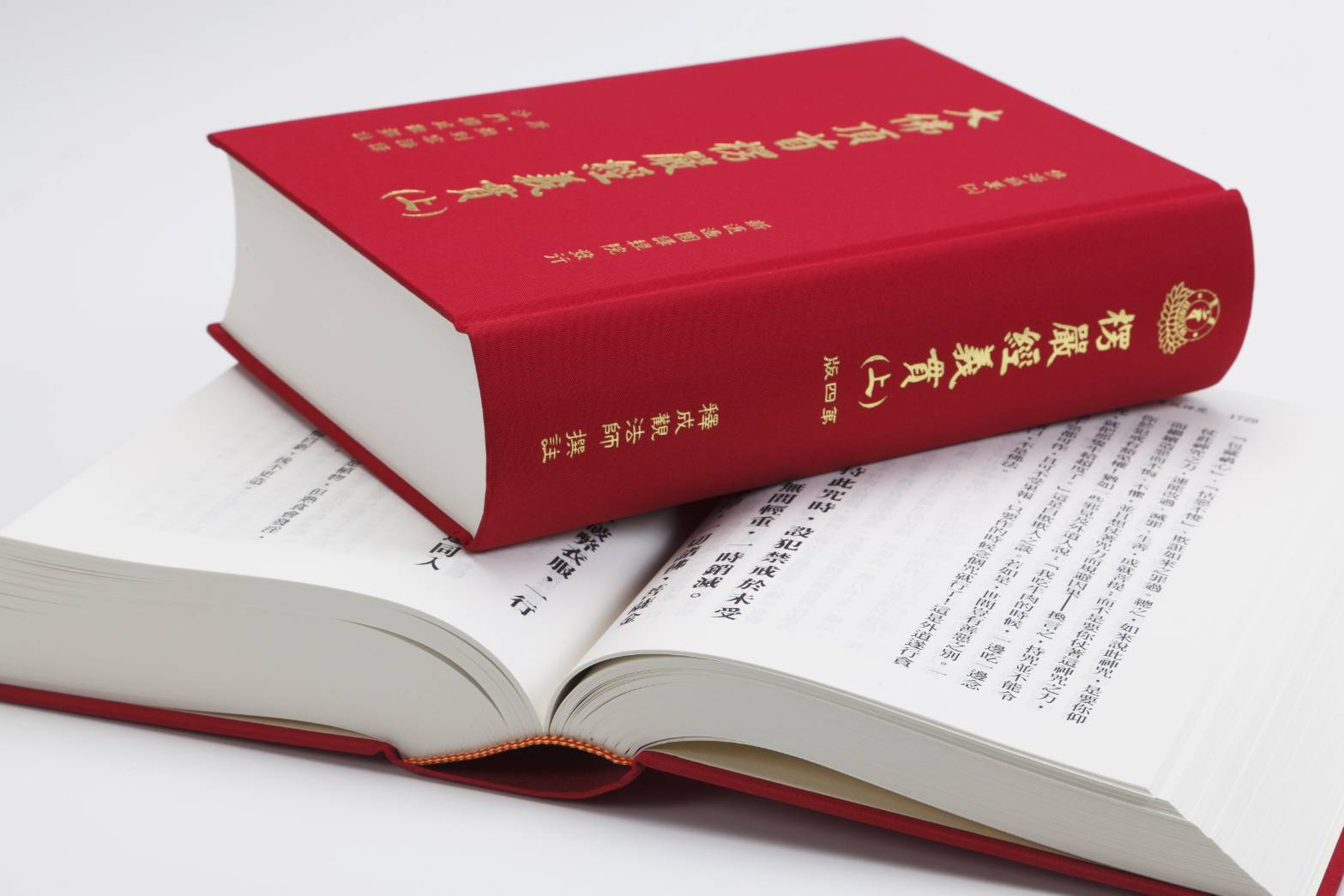

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.