Commodity Boxes Printing

-

sentiment_very_satisfied

Viewers:

- 461

Commodity boxes printing, Printed commodity boxes, Custom commodity packaging, Box printing for commodities, Product packaging printing

-

Folding Cartons: Foldable boxes made from paperboard, commonly used for packaging small consumer goods such as cosmetics, pharmaceuticals, and confectionery items.

-

Corrugated Boxes: Sturdy and lightweight boxes constructed from corrugated cardboard, ideal for shipping and storing heavier products like electronics, appliances, and bulk items.

-

Rigid Boxes: High-end, premium-quality boxes made from rigid board materials, often used for luxury goods, gift items, and special promotions.

-

Display Boxes: Transparent or windowed boxes designed to showcase products while providing protection and visibility on retail shelves, commonly used for electronics, toys, and cosmetics.

-

Mailer Boxes: Self-sealing boxes with built-in tabs or adhesive strips, suitable for shipping smaller items directly to customers in e-commerce and subscription-based businesses.

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.

The content related to paper box printing production:

- Size Format: Dimensions of the paper box in length x width x height in centimeters.

- Paper Types: Single copperplate, gray copper card, drill card paper, watermarked white card paper, white copper card paper, copper west card paper, art paper (imported paper).

- Mounting Corrugated Paper: Mounting E wave, mounting white E wave, mounting B wave, mounting F wave, mounting kraft paper, mounting E wave + B wave.

- Paper Thickness: Paper thickness (250 pounds, 300 pounds, 350 pounds, 400 pounds, 500 pounds, 600 pounds).

- Printing Colors: Six-color printing, five-color printing, four-color printing, two-color printing, monochrome printing.

- Printing Quantity: Quantity.

- Sampling Method: Digital sampling or formal sampling (direct machine printing sampling or sampling).

- Die Cutting Types: General die cutting, Japanese die cutting, Swiss die cutting, steel die cutting, laser die cutting, metal die cutting.

- Box Surface Treatment: Water-based gloss, gloss, matte, suede, frosted, matt, or partial gloss, UV gloss (UV is divided into gloss UV, frosted UV, release UV).

- Special Techniques: Skylight, hand-held handle, transparent film pasting, hot stamping gold and silver, copper button pressing.

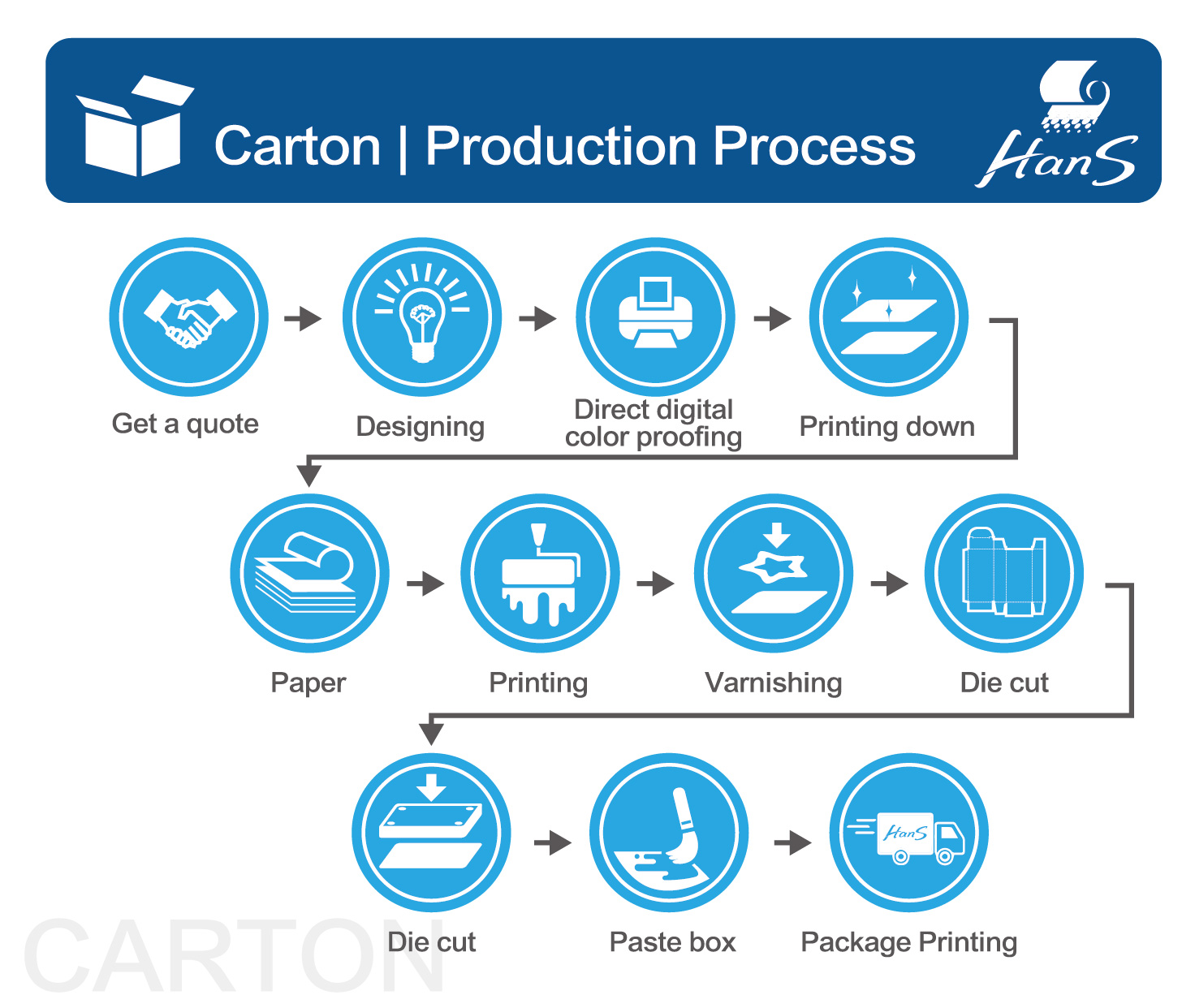

The paper boxes printing production process:

Quotation and contract signing ==> Design ==> Final draft editing ==> Proofreading ==> Digital sample printing (for formal sample) ==> Paper printing ==> Mounting on corrugated board ==> Plate exposure ==> Printing ==> Glossing ==> Die cutting ==> Assembly ==> Handmade box ==> Packaging and shipping (1-month process)

Commodity packaging design, Printed box solutions for commodities, Custom box printing services, Packaging printing for products, Branded commodity boxes