Hardcover Book Printing

-

sentiment_very_satisfied

Viewers:

- 574

Hardcover Books: A Legacy of Craftsmanship and Storytelling

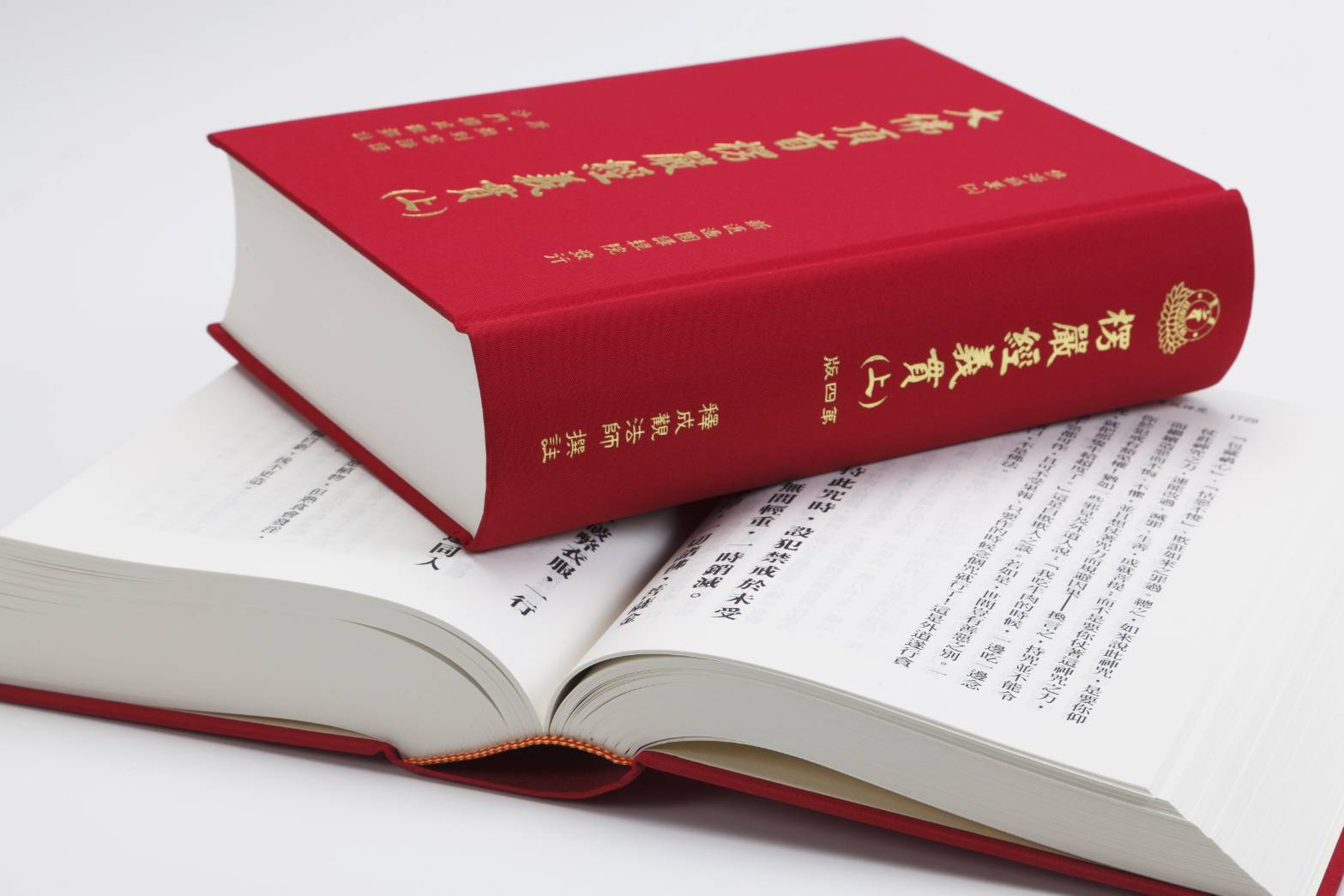

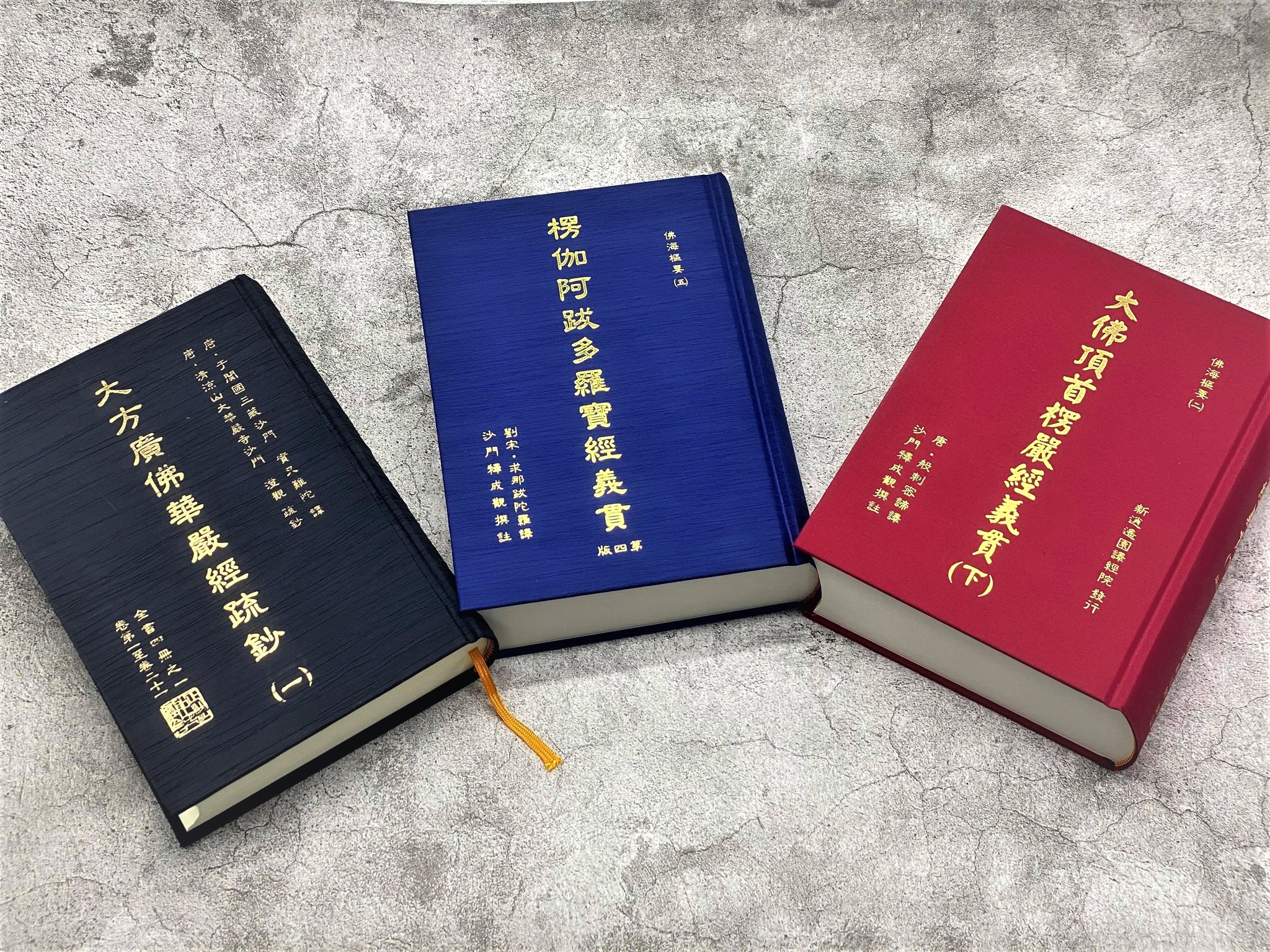

Hardcover books—also known as hardback books, hardbound books, or case-bound books—represent the pinnacle of printed publishing.

Whether it's a classic novel, academic textbook, or commemorative edition, these books stand as enduring symbols of knowledge, creativity, and storytelling. The process of hardcover book printing blends craftsmanship, precision, and meticulous attention to detail, resulting in literary works that are not only timeless but also physically resilient and visually compelling.

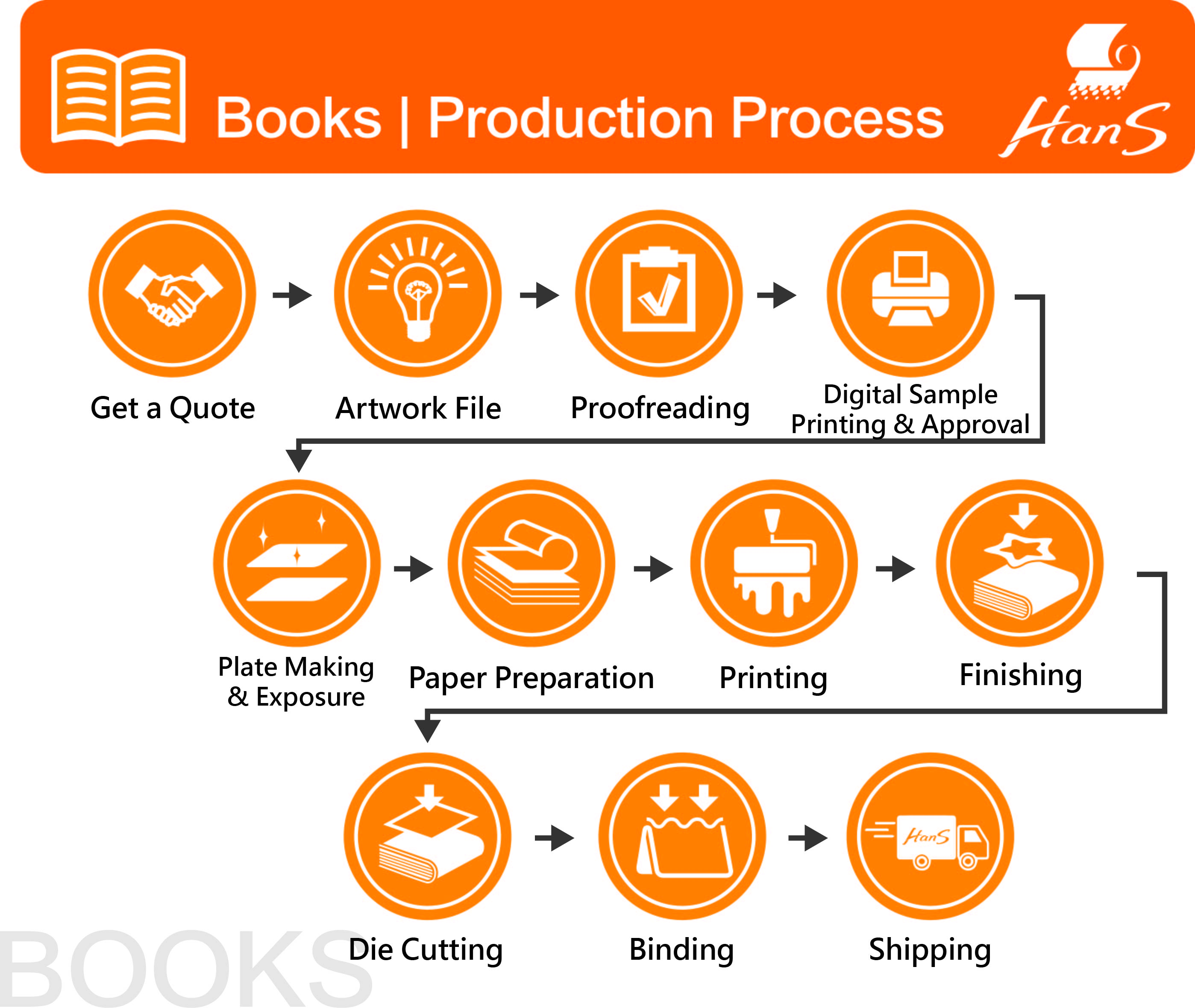

Design & Specifications

Design and Layout

Hardcover book production begins with the design phase, where visual elements and content layout are carefully planned. Designers consider cover aesthetics, typography, formatting, and genre-specific styles to ensure the book resonates with its target audience.

Cover Material and Finishing

The hardcover—also known as the case or binding cover—is typically made from durable materials such as greyboard, cloth, or leatherette. Enhancements like embossing, foil stamping, spot UV, or dust jackets add visual appeal and elevate the book’s perceived value.

Printing Techniques

Hardcover books are printed using either offset or digital printing:

- Offset printing offers superior color accuracy and is ideal for large print runs.

- Digital printing provides flexibility for small quantities, faster turnaround, and customization options.

Paper Selection

The choice of paper for the book’s interior pages significantly affects its overall texture and reading comfort. Common considerations include:

- Paper weight (thickness in gsm)

- Surface texture (smooth or textured)

- Finish type (matte or glossy)

These factors collectively determine the book’s visual presentation and tactile experience.

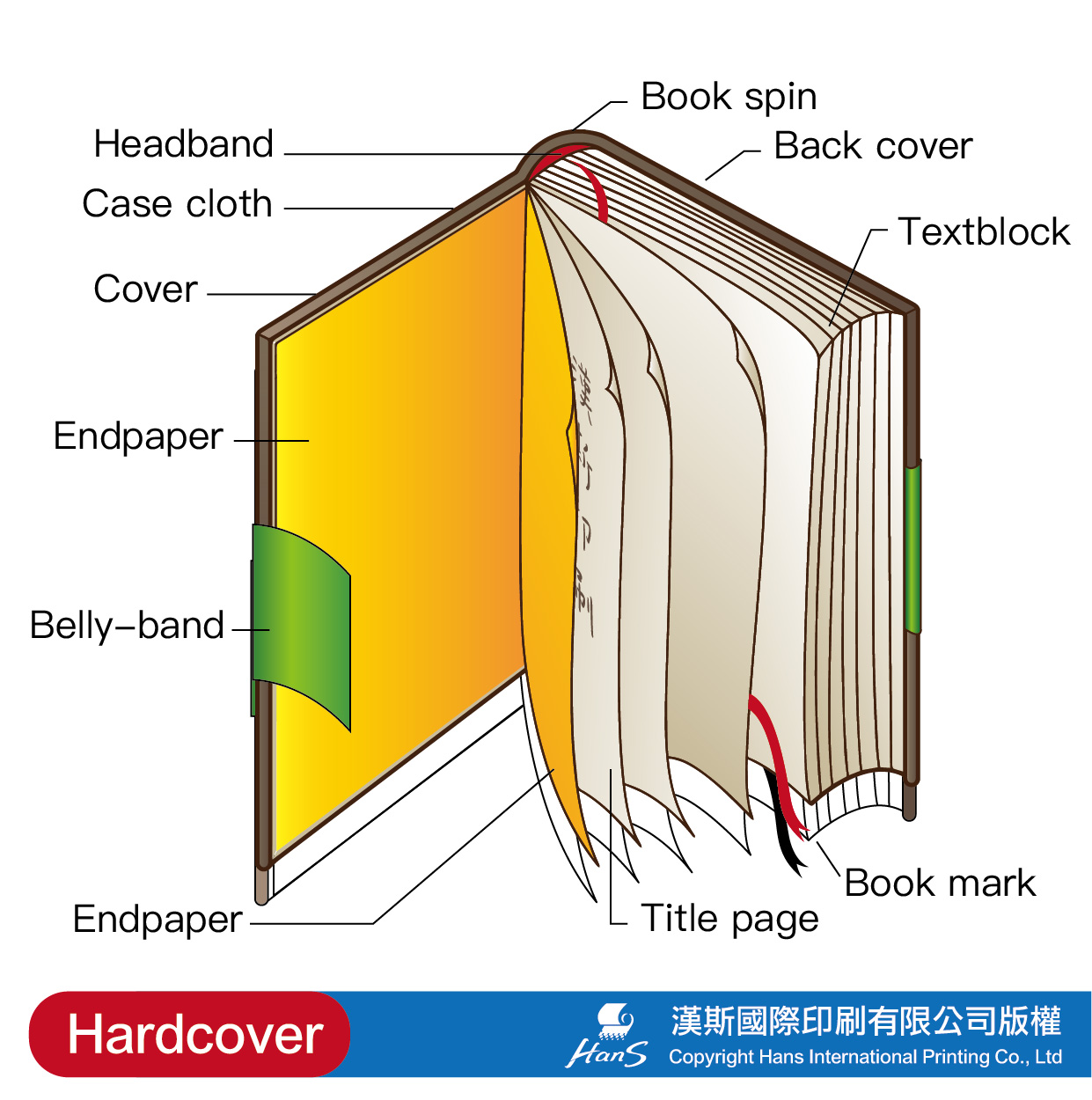

Binding Methods

Hardcover books are bound using:

- Adhesive (case) binding, where pages are glued to the spine

- Sewn binding, where signatures are stitched together before casing in

Sewn binding offers greater durability and allows the book to lay flat when opened—ideal for premium editions.

Quality Control

Rigorous quality checks are conducted throughout production to ensure consistency and excellence. These include:

- Color accuracy

- Print registration

- Paper quality and binding strength

These checks ensure that every book meets the required standards and reflects a high level of craftsmanship.

Customization and Special Features

Hardcover printing supports a wide range of enhancements to create distinctive, collectible editions:

- Foil stamping, spot UV, and embossed covers

- Gilded edges, ribbon markers, and slipcases

These features add emotional and aesthetic value, making the book a treasured gift or keepsake.

Hardcover Book Options & Specifications

******************************************************************************

Drop Your Question!

We’re here to help—feel free to reach out anytime.

- Email: han666@hanfom.com

WhatApp Business: +886 910 243 496

- Ms. Christine — International Sales Representative

Mobile/WhatsApp: +886 910 225 861

(Available GMT+8: 08:30-12:00 | 13:00-17:30 | 21:00-22:00)

- Mr. Huang — Domestic Sales Representative / Printing Specialist

Mobile: +886 910 243 496

(Available GMT+8: 08:00-20:00)