Digital Printing And Offset Printing

-

sentiment_very_satisfied

Viewers:

- 0

Offset Printing vs Digital Printing

Offset Printing and Digital Printing are two predominant methods in the printing industry, each with its own set of advantages and disadvantages. |

|

1. OverviewOffset printing, also known as lithography, is a traditional printing method that involves transferring ink from a plate to a rubber blanket and then onto the printing surface. This method is highly efficient for large print runs. 2. How It Works- Plate Preparation: Metal plates are created for each color used in the print job. - Inking: Ink is applied to the plates, and the image is transferred to a rubber blanket. - Printing: The rubber blanket presses the image onto the paper or other material. 3. Advantages- High Image Quality: Produces sharp and clean images with precise color reproduction. - Cost-Effective for Large Runs: Economical for high-volume print jobs due to lower cost per unit as the quantity increases. - Wide Range of Paper Options: Can print on various paper types and weights. - Pantone Color Matching: Ability to use specific Pantone colors for accurate brand color reproduction. 4.Disadvantages- High Initial Setup Cost: Expensive setup process due to plate creation, making it less cost-effective for small runs. - Longer Turnaround Time: Requires more setup time, which can lead to longer production times. - Limited Customization: Not ideal for variable data printing or on-demand changes. |

1. OverviewDigital printing is a modern method that involves transferring a digital image directly onto the printing surface using advanced printing technology. It is ideal for short to medium print runs and personalized printing. 2. How It Works- Image Creation: A digital file is created using graphic design software. - File Processing: The file is processed by a Raster Image Processor (RIP). - Printing: The image is printed directly onto the material using inkjet or laser technology. 3. Advantages- Quick Turnaround: Faster production times due to minimal setup. - Cost-Effective for Small Runs: No setup costs make it economical for short print runs. - Customization: Ideal for variable data printing, allowing for personalized prints. - On-Demand Printing: Can print only what is needed, reducing waste and storage costs. - High-Quality Output: Advances in technology have significantly improved the quality of digital prints, making them comparable to offset prints. 4. Disadvantages- Higher Cost Per Unit for Large Runs: More expensive per unit compared to offset printing for high volumes. - Limited Color Matching: May struggle with exact color matching, especially for specific Pantone colors. - Substrate Limitations: Not all digital printers can handle the same range of substrates as offset printing. |

-

Comparison

| Offset Printing | Digital Printing | |

| Setup Cost | High (due to plate creation) | Low |

| Cost Per Unit | Low for large runs | Higher for large runs |

| Turnaround Time | Longer (due to setup process) | Shorter (minimal setup) |

| Print Quality | High (sharp images, accurate colors) | High (improved with technology advancements) |

| Color Matching | Excellent (Pantone color matching) | Good (less precise for specific colors) |

| Customization | Limited | Excellent (variable data printing) |

| Best For | Large print runs, consistent quality | Short runs, personalized prints, quick jobs |

| Material Options | Wide range of paper types and weights | Limited to compatible substrates |

| Environmental Impact | More waste due to setup and overproduction | Less waste, on-demand printing |

|

Both offset and digital printing have their own strengths and are suitable for different types of projects.

- Choose Offset Printing if you need high-quality, large-volume prints with specific color matching and a wide range of material options. - Choose Digital Printing if you need quick turnaround, personalized prints, and cost-effective solutions for short runs or on-demand printing.

Understanding your specific needs, budget, and timeline will help you determine the best printing method for your project. |

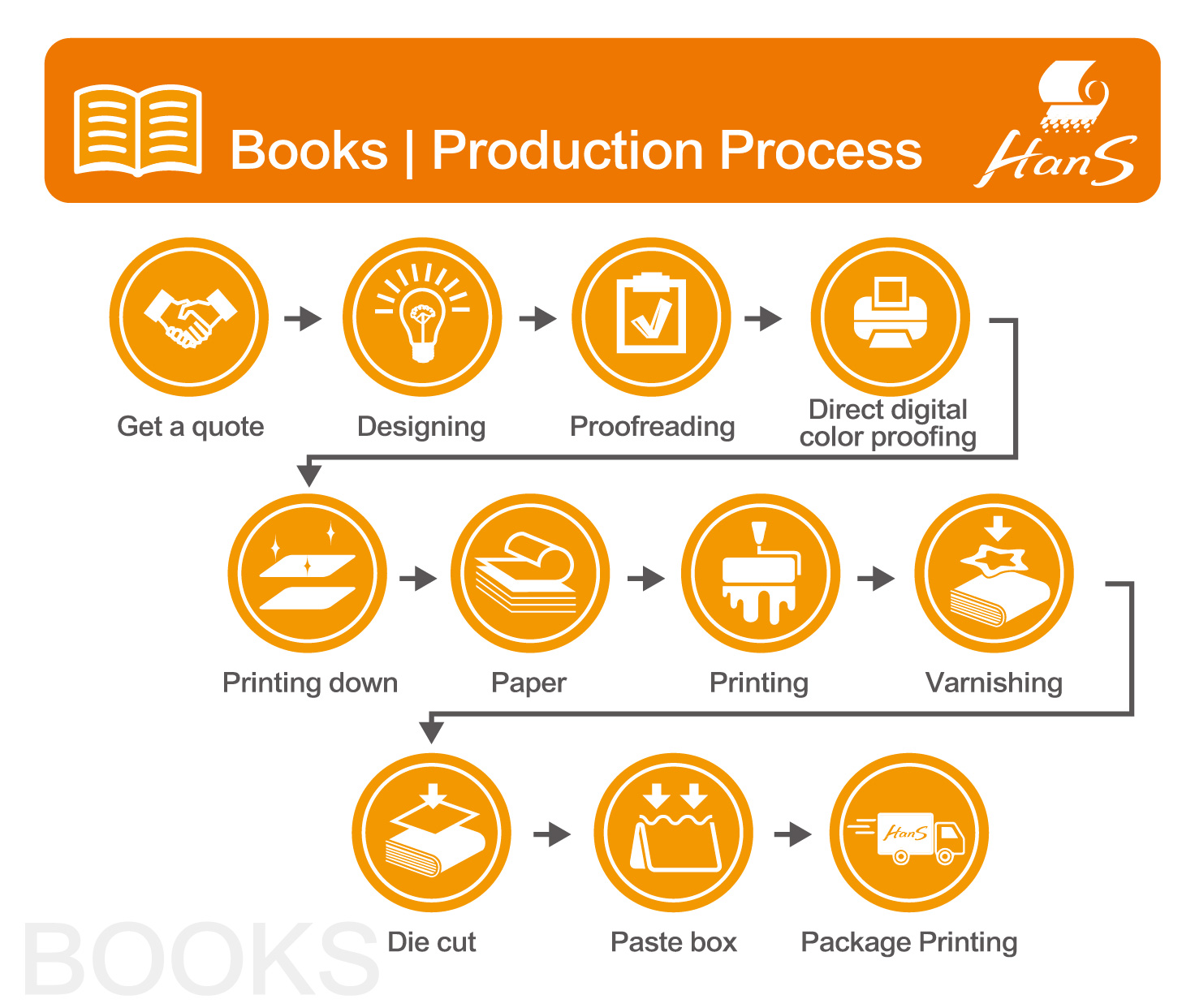

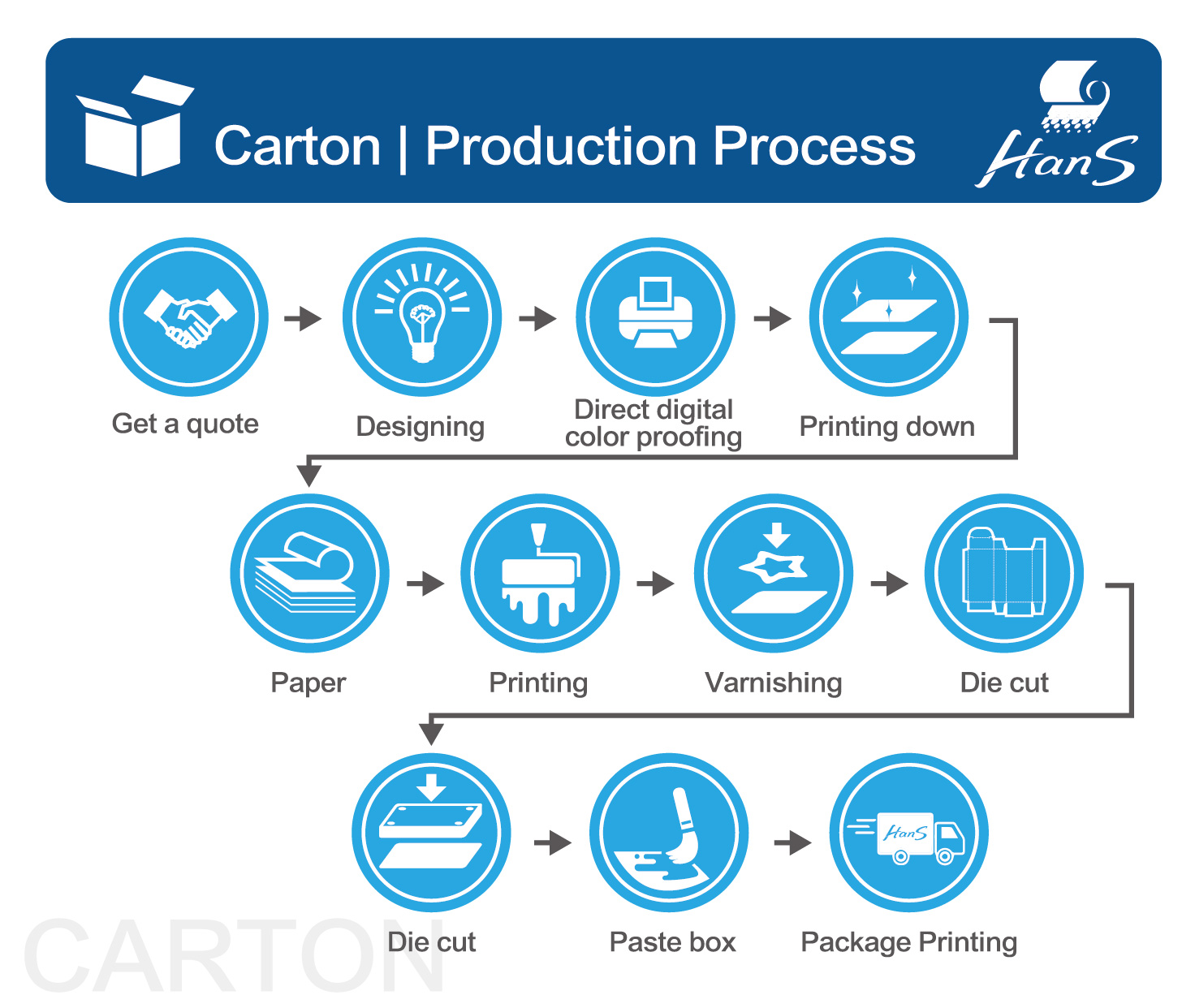

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.