Label Logo Printing

-

sentiment_very_satisfied

Viewers:

- 456

1. Design Considerations

- Clarity and Readability:

Ensure that your logo is easily recognizable and readable at various sizes. Logos that are too complex may lose detail when printed on small labels.

- Color Scheme:

Choose colors that align with your brand identity and are also practical for printing. Keep in mind that some colors may vary between digital designs and physical prints due to different color models (RGB vs. CMYK).

- Material Compatibility:

The design should be adaptable to different label materials, whether you're using paper, plastic, metallic surfaces, or textiles.

2. Printing Techniques

- Digital Printing:

Ideal for high-quality, detailed logos, especially for short runs or labels requiring variable data printing (VDP). Digital printing allows for vibrant colors and is relatively quick and cost-effective for small to medium quantities.

- Flexography:

Suitable for large runs, flexography is a more traditional form of printing that uses flexible printing plates. It’s efficient for printing on a wide variety of materials and is known for its durability and speed.

- Screen Printing:

Offers a high level of vibrancy with inks that stand out, even on darker materials. Screen printing is particularly good for textiles and large, bold designs on labels.

- Offset Printing:

Best for high-volume orders, offset printing provides excellent color accuracy and detail. It's more cost-effective at larger scales but involves longer setup times.

.jpg)

.jpg)

3. Material Choices

- Paper Labels:

Versatile and cost-effective, paper labels are suitable for a wide range of products but are best for indoor use as they are less durable and water-resistant than other materials.

- Vinyl Labels:

Durable and waterproof, vinyl labels are great for products that may be exposed to moisture or outdoor conditions. They can support vibrant colors and detailed designs.

- Polyester (PET) Labels:

Known for their strength and resistance to tearing, moisture, and UV light, PET labels are ideal for products requiring long-lasting labels under harsh conditions.

- BOPP (Bi-axially Oriented Polypropylene):

Resistant to water, oil, and chemicals, BOPP is perfect for food and beverage products, cosmetics, and any product that encounters moisture or greasy conditions.

4. Finishing Touches

- Laminates and Varnishes:

Protect your labels and logos with laminates or varnishes that can enhance durability and resistance to fading, moisture, and scratches.

- Embossing or Debossing:

These techniques can add a tactile dimension to your logo, making it stand out visually and to the touch.

- Foiling:

Metallic foils can be applied to certain areas (such as your logo) for a premium look that catches the eye.

5. Regulatory Compliance

Ensure that your label logo printing complies with any relevant regulations or standards, especially for products in regulated industries like food, beverages, cosmetics, and pharmaceuticals. This may include specific labeling requirements regarding size, information, and placement.

.jpg)

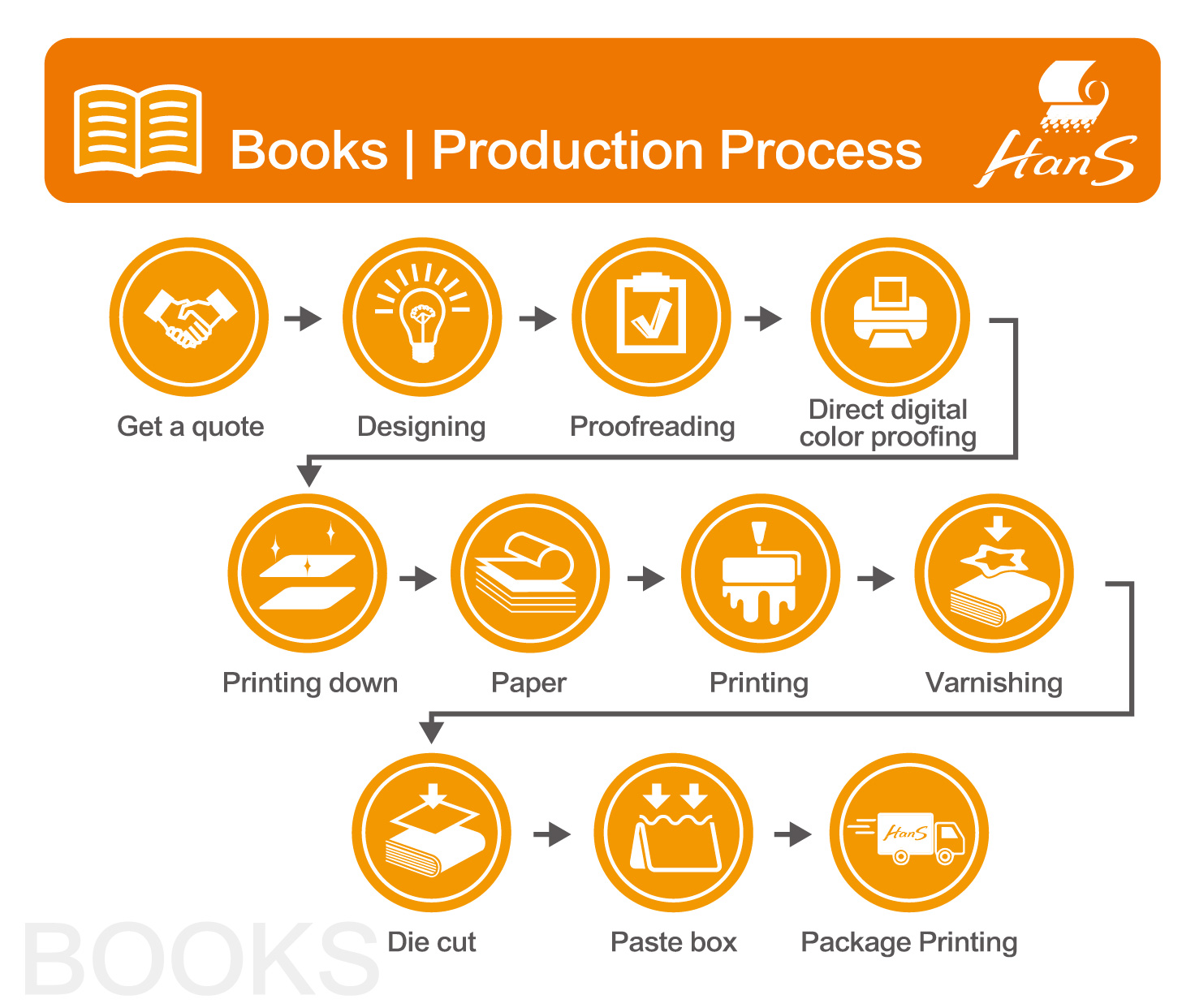

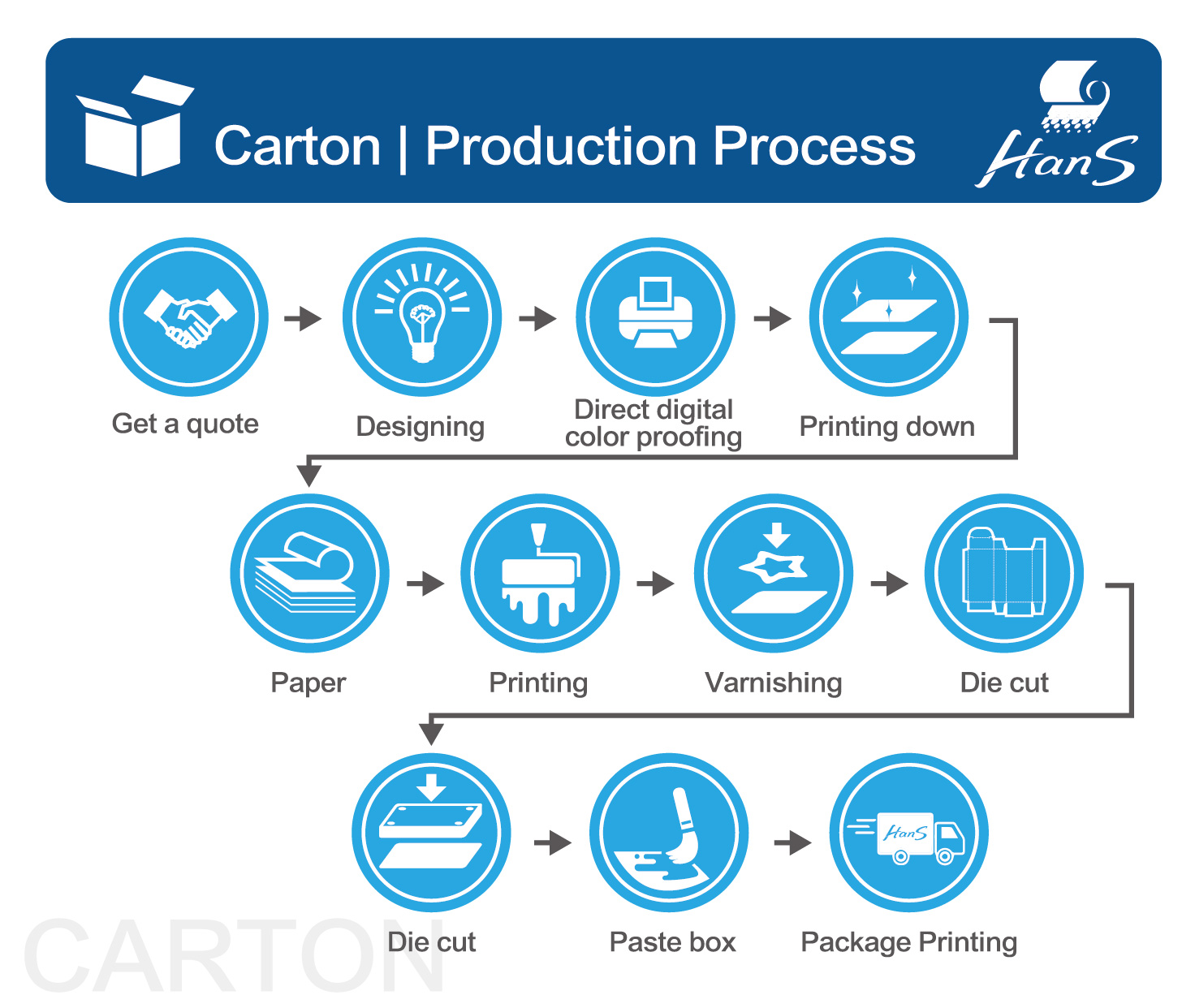

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.