Custom box for printing

-

sentiment_very_satisfied

Viewers:

- 515

1. Define Your Purpose

First, clarify the purpose of your custom box. Is it for shipping, display, or as a gift box? The intended use will guide the design, material selection, and strength requirements.

2. Choose the Right Material

Select a material that suits your box's purpose:

- Cardboard: Versatile, recyclable, and perfect for a variety of uses from shipping to retail packaging.

- Corrugated Fiberboard: Offers more strength and durability for shipping or heavier items.

- Paperboard: A lighter option, ideal for cosmetics, pharmaceuticals, and small consumer goods.

3. Design Your Box

Design involves both the structural and graphical aspects:

- Structural Design: The box's shape, size, and functionality. Consider how the box opens, the protection it offers, and how it will display the product.

- Graphic Design: This covers the visual appearance, including brand colors, logos, images, and text. The design should reflect the brand identity and appeal to the target audience.

4. Select Printing Techniques

Choose a printing method that aligns with your design complexity, color fidelity needs, and budget:

- Digital Printing: Ideal for high-detail, vibrant designs and cost-effective for small to medium runs.

- Lithography: Offers high-quality prints with excellent color accuracy, suitable for larger volumes.

- Flexography: Good for simpler designs and large volumes, often used for shipping and food packaging.

- Screen Printing: Works well for specific materials and offers vibrant, opaque colors.

5. Consider Finishing Options

Finishing touches can enhance the look and feel of your box:

- Lamination: Adds a glossy or matte protective layer.

- UV Coating: Provides a shiny, durable finish that's resistant to scratches and fading.

- Embossing/Debossing: Creates a raised or recessed relief for a tactile effect.

- Foil Stamping: Adds a metallic finish for a premium look.

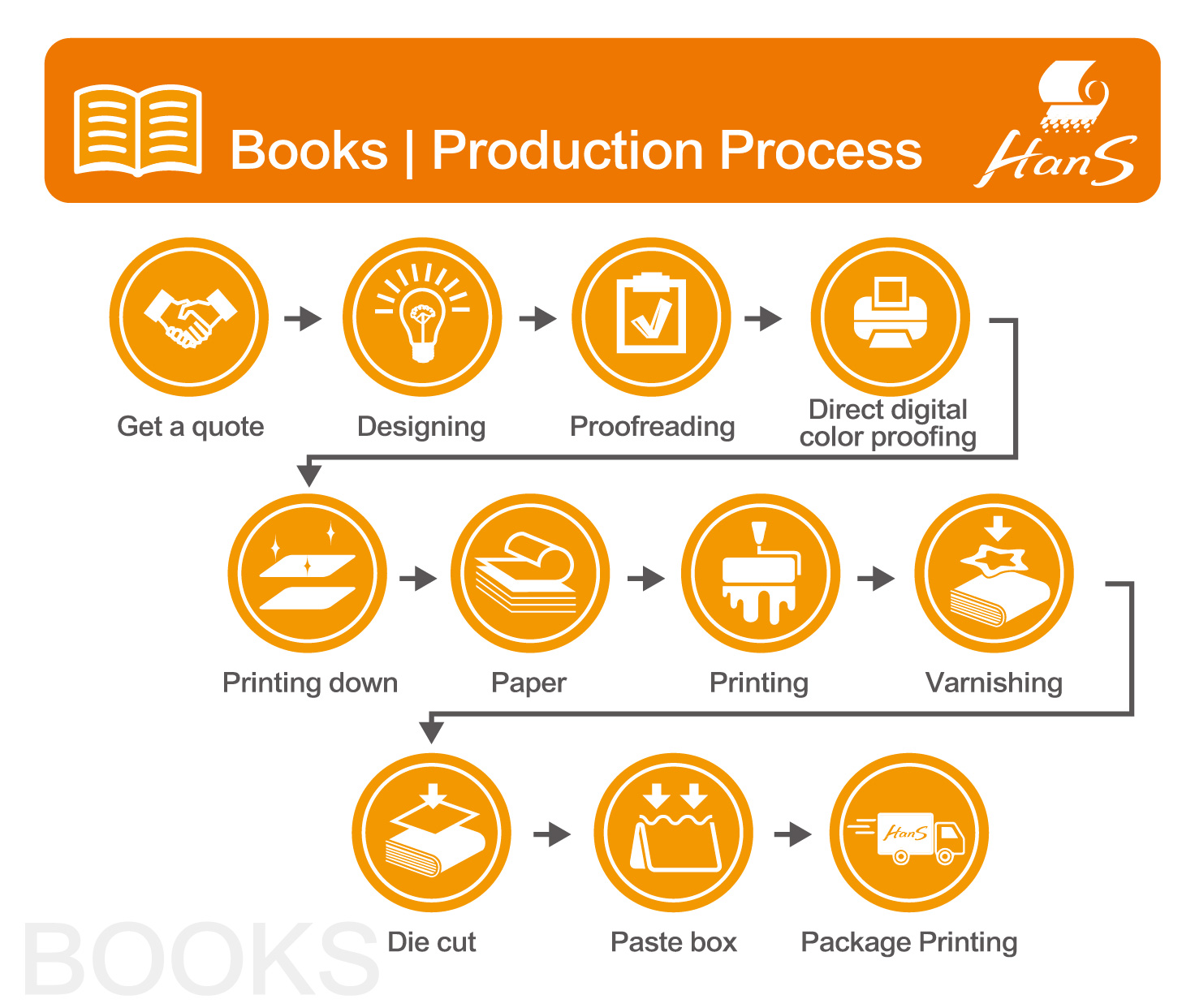

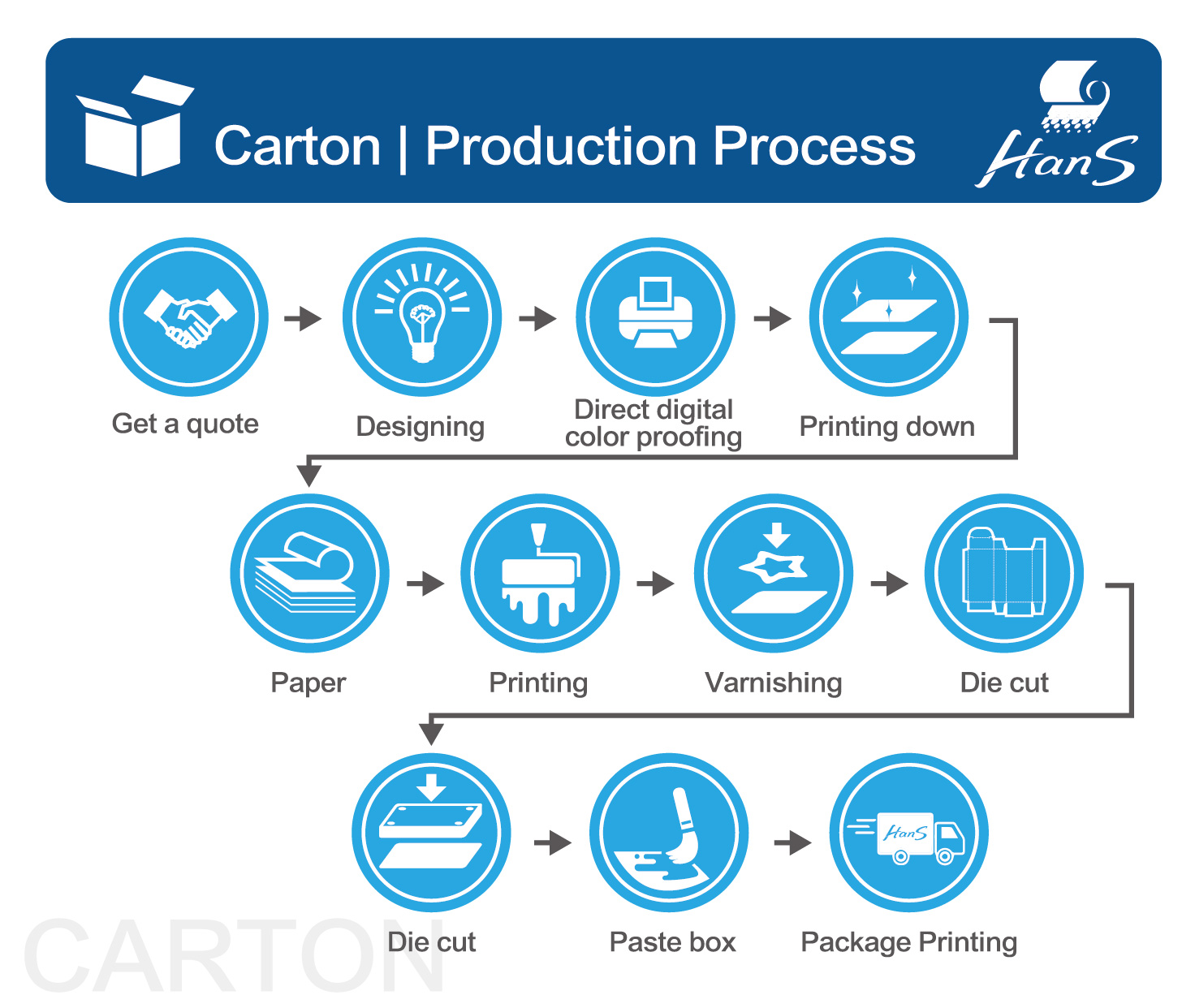

6. Prototype Your Design

Before moving to mass production, create a prototype to examine the box's design, material, and structural integrity. This step can help you make necessary adjustments to avoid costly errors in the production phase.

7. Choose a Manufacturer

Select a reputable manufacturer that can meet your quality, quantity, and turnaround time requirements. Provide them with your design files, material specifications, and any other relevant details. It’s also wise to discuss their production capabilities, quality control processes, and sustainability practices.

8. Production and Quality Control

Once you approve the prototype, production begins. Ensure there's a quality control process in place to check for consistency, color accuracy, and structural integrity.

9. Packaging and Distribution

Finally, consider how your boxes will be packed and distributed. Ensure they are adequately protected during transit to maintain their quality and appearance upon arrival.

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.