Hans International printing custom boxes for printing

-

sentiment_very_satisfied

Viewers:

- 893

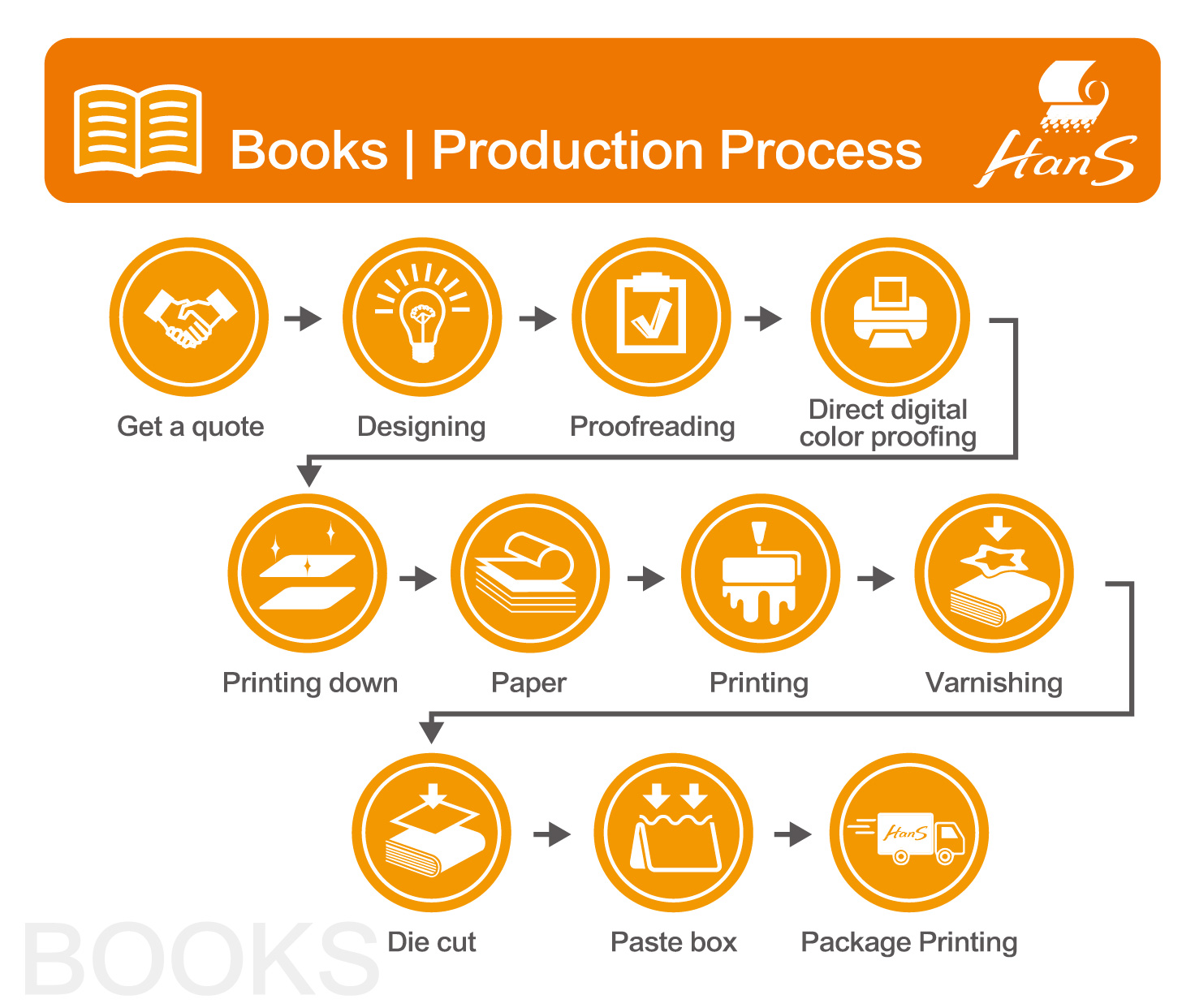

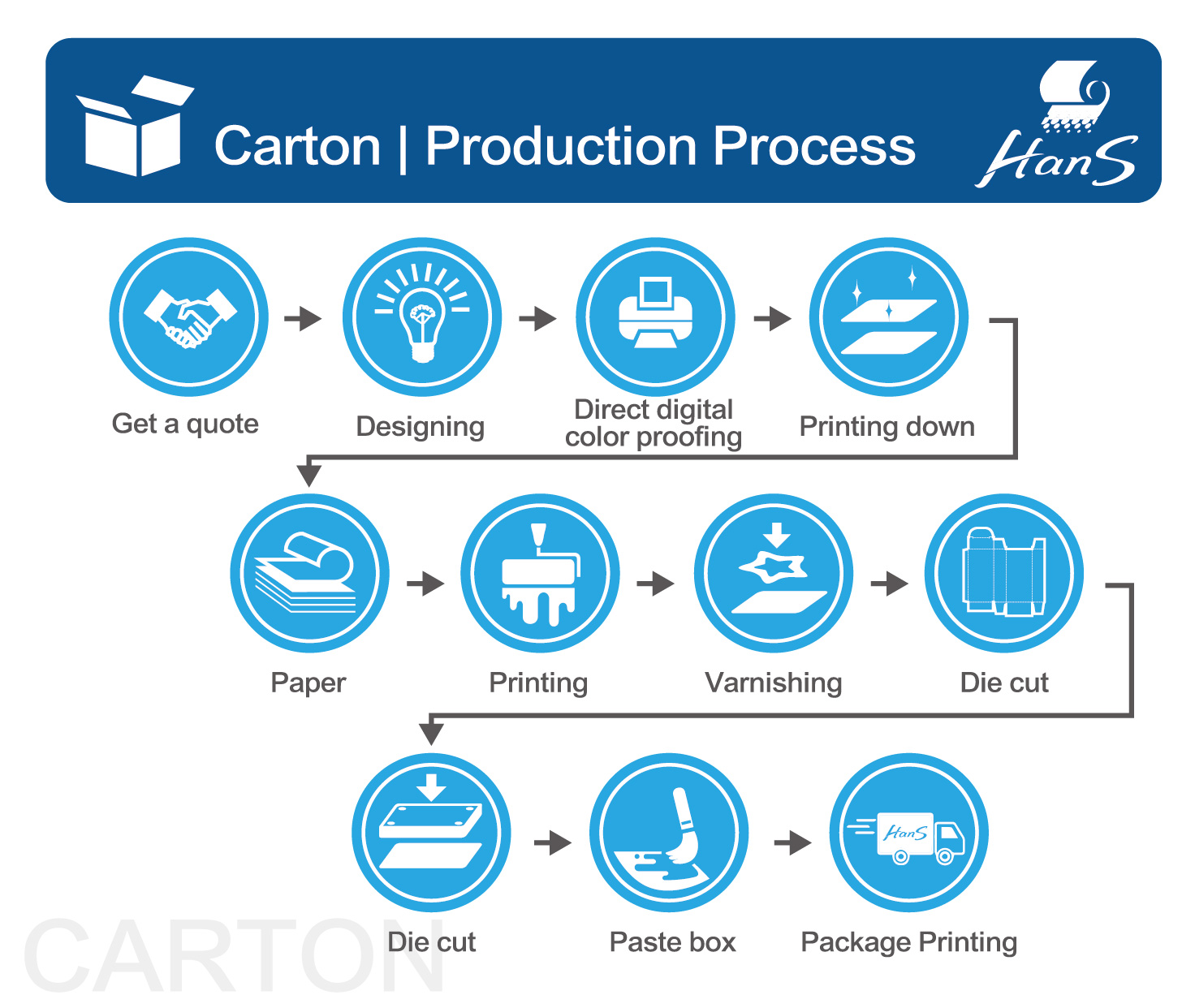

1. Concept and Design

-

Define the Purpose:

Determine the primary function of your boxes (e.g., shipping, product packaging, gift boxes). Consider the size and weight of the items they will contain.

-

Design the Box:

This involves creating a template or die-line of the box, which maps out all the folds, cuts, and glue areas. Design software like Adobe Illustrator is commonly used for this purpose.

-

Graphic Design:

Apply your branding elements, such as logos, colors, and any text or imagery that will appear on the box. The design should be engaging and reflective of the brand identity.

2. Material Selection

-

Choose the Right Material:

Options typically include various types of cardboard, corrugated fiberboard, or paperboard, depending on the box's required durability and the printing method. Consider environmental factors and the need for recycled or recyclable materials.

3. Prototyping

-

Mock-up or Sample:

Before full-scale production, a prototype or sample box is made. This helps in assessing the design, fit, and function. Adjustments can be made at this stage without incurring the costs associated with full production.

4. Printing Process

Select a Printing Technique:

The main printing methods for custom boxes include:

-

Digital Printing:

Suitable for small to medium runs with high detail and color variation. It allows for quick changes and short turnaround times.

-

Lithography:

Ideal for high-quality print on flat paper or cardboard, which is then laminated to corrugated board. It's cost-effective for larger runs.

-

Flexography:

Often used for larger quantities and when a simpler design or fewer colors are involved. It can print directly on corrugated board.

-

Screen Printing:

Used for specific materials and for boxes requiring vibrant, opaque colors.

-

Printing:

The chosen design is printed onto the material. The complexity of the design and the printing method used can affect the cost and time required for this step.

5. Finishing Touches

-

Finishing Options:

After printing, various finishing options can enhance the box's appearance and durability. Options include lamination (glossy or matte), UV coating, embossing, debossing, and foil stamping.

-

Die Cutting and Gluing:

The printed material is then die-cut according to the box template and glued or assembled into the final shape.

6. Quality Check

-

Inspection:

Each box or a batch of boxes is inspected for quality, ensuring that the printing, cutting, and gluing adhere to the specified requirements.

7. Packaging and Delivery

-

Packaging:

The boxes are packed to protect them during shipping.

-

Delivery:

The completed boxes are delivered to the client or directly to a fulfillment center, ready for use.

This process requires close coordination between the client and the manufacturer to ensure that the final product meets the desired specifications and quality standards. Advances in technology and materials continue to expand the possibilities for custom box printing, offering businesses innovative ways to showcase their brands and package their products.

Cardboard Gift Box, Magnetic Gift Box, Drawer Gift Box, Candle Gift Box, Paper Box, Corrugated Box, Folding Paper Box, Perfume Packaging Box, Apparel Packaging Box, Electronic Packaging Box, Cosmetic Packaging Box, Food Packaging Box, Jewelry Packaging Box, Toy Packaging Box, Kitchenware Packaging Box

From planning and filing to the completion of printed matter, printing must go through many procedures, combined with the professional skills of countless people, such as graphic designers, commercial photographers, copywriters, typewriters, artists, color separation technicians, printing technicians, Public workers, printing technicians, bookbinding, varnishing and various processing technicians, etc., without any one, can not successfully complete the printed matter, so they are all important contributors.

We assist many enterprises and organizations in the integrated planning and production of printed materials, focusing on providing comprehensive printing integration services, helping you think more, do more, and win more under limited time and money.